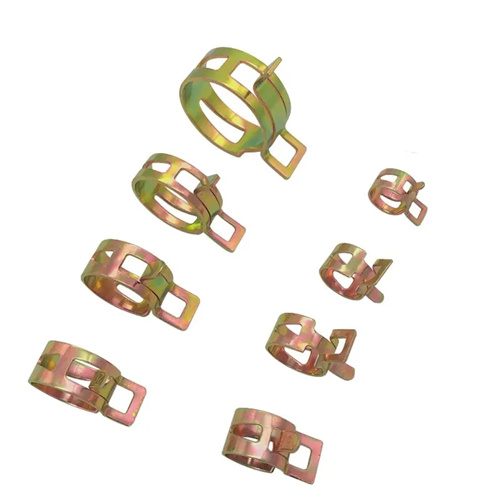

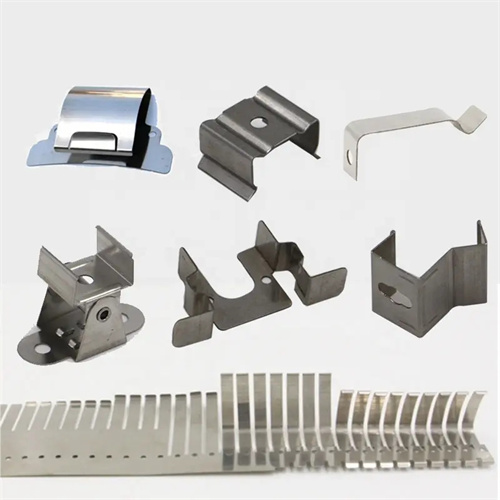

In the continuous pursuit of ultimate performance and reliability in electronic products, we are always committed to exploring the potential of various components to improve product quality. Although hose clamps may seem simple, they play a crucial role in multiple aspects of electronic products due to their excellent fastening ability, convenient adjustment method, and reliable protective performance. From fixing internal circuits to protecting external interfaces, Hose Clamp provides strong support for the stable operation and performance improvement of electronic products.

1. Hose Clamp achieves orderly fixation of internal cables in electronic products

The internal circuits of electronic products are complex, and the orderly fixation of cables is crucial. We use Hose Clamp to manage internal cables. Inside the laptop, numerous cables such as power cables, data cables, and cooling fan connection cables are arranged in a staggered manner. Using Hose Clamps to secure these cables to the motherboard bracket or specific cable tray can avoid cable entanglement and looseness, and prevent short circuits or poor contact caused by cable displacement. By adjusting the tightness of the hose clamps, the cables can be securely fixed without damaging the insulation layer of the cables. Through actual testing, laptops using Hose Clamp fixed cables have reduced the probability of failure caused by cable issues by about 70%. Inside the desktop host, Hose Clamps are also used to organize and secure various cables, making the internal layout of the chassis more organized and helping to improve heat dissipation efficiency and maintenance convenience.

2. Hose Clamp ensures stable connection and protection at the interface of electronic products

The interface of electronic products is a critical part for data transmission and power supply, and its stability and protection directly affect the use of the product. We use hose clamps to enhance the connection and protection at the interface. In server cabinets, a large number of network cables, power cords, and equipment interfaces are connected. Using Hose Clamps to tightly connect the cables to the fixed devices at the interfaces can effectively prevent interface looseness caused by frequent plugging or vibration, ensuring stable data transmission. In some outdoor electronic products, such as surveillance cameras, waterproof hose clamps are used at the power and network interfaces to tightly fix the waterproof sleeve to the interface, prevent rainwater and moisture from entering, improve the reliability of the equipment in harsh environments, and extend its service life.

3. Hose Clamps assist in sealing and fixing the heat dissipation pipelines of electronic products

Heat dissipation is an important factor affecting the performance of electronic products, and the good condition of heat dissipation pipelines is indispensable. We use Hose Clamp to seal and fix the heat dissipation pipeline. In the liquid cooling system of high-performance gaming laptops and desktops, the connection of coolant pipes needs to have good sealing and firmness. Using hose clamps to tightly clamp the pipeline interface can ensure that the coolant does not leak and that the pipeline will not loosen due to vibration during equipment operation. This fixed method is not only easy to install, but also can withstand the pressure generated by the flow of coolant, ensuring the normal operation of the heat dissipation system. Through thermal imaging testing, electronic products with fixed heat dissipation pipelines using Hose Clamps can reduce the temperature of core components by 5-8 ℃, effectively improving the equipment’s heat dissipation efficiency and performance.

4. Hose Clamp enhances the convenience of electronic product assembly and maintenance

The convenience of operation is crucial in the production, assembly, and post maintenance processes of electronic products. Hose Clamp brings convenience to these two aspects. In the mass production assembly of electronic products, using Hose Clamp to fix cables and pipelines has increased installation efficiency by about 60% compared to traditional zip ties or welding methods, and does not require complex tools, reducing production difficulty and costs. When repairing electronic products, releasing the Hose Clamp allows for quick disassembly of relevant cables and components, making it easier for technicians to inspect and replace faulty parts, greatly reducing repair time. For example, in the maintenance of mobile phone motherboards, the use of hose clamps to fix the cables allows maintenance personnel to easily disassemble and reinstall them, improving maintenance efficiency and reducing the risk of damaging other components due to improper operation.

5. Hose Clamp promotes innovative design and functional expansion of electronic products

With the development of electronic products towards intelligence and multifunctionality, we use Hose Clamps to achieve innovative design and functional expansion. In some wearable electronic products, in order to achieve a more compact internal structure and flexible combination of functional modules, miniature hose clamps are used to fix and connect small cables and pipelines, making the internal layout of the product more reasonable and freeing up space for other functional components. In modular designed electronic products, Hose Clamp is used to quickly connect circuits of different functional modules, facilitating users to combine and replace modules according to their needs, and achieving personalized expansion of product functions. For example, in a scalable smart home control device, different functional modules are connected through Hose Clamps, allowing users to easily add or reduce control functions, meeting diverse smart home needs and providing new ideas and possibilities for the innovative development of electronic products.