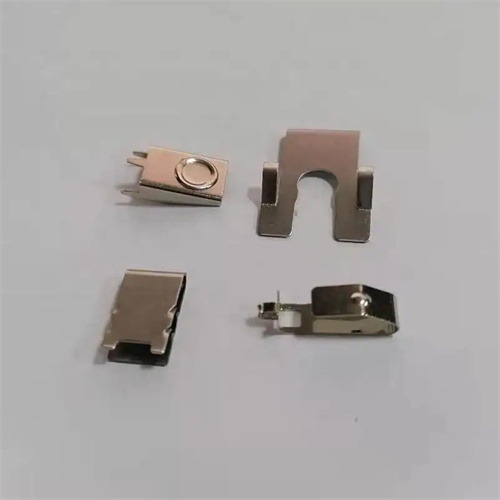

On the path of continuous development and innovation in the construction industry, we are always committed to finding reliable technologies and components to ensure the quality and safety of construction projects. Although seemingly simple, Retainer Clips play a crucial role in various fields of the construction industry, such as plumbing systems, electrical wiring, HVAC installations, etc., thanks to their excellent fastening performance, convenient installation methods, and flexible adaptability. They provide a solid guarantee for the stable operation and long-term use of building systems.

1. Retainer Clips ensure stable connection of building plumbing and drainage systems

In the water supply and drainage engineering of buildings, the sealing and stability of pipeline connections directly affect the normal operation of the system. We use Retainer Clips to achieve reliable fixation of water supply and drainage pipelines. In the installation of water supply pipelines in high-rise buildings, Retainer Clips are used to fasten the interfaces of pipelines with different diameters, which can evenly apply pressure and make the pipeline sealing ring tightly fit, effectively preventing water leakage. Whether it’s metal or plastic pipes, Retainer Clips can quickly adapt and provide stable clamping force. After testing, the water supply and drainage pipes connected with Retainer Clips reduced the leakage rate by about 85%. In the drainage system, Retainer Clips also play a role in firmly connecting drainage pipes and fittings, avoiding pipe loosening and disconnection caused by water flow impact or building settlement, and ensuring the smooth flow of the drainage system.

2. Retainer Clips achieve orderly fixation and protection of building electrical circuits

The standardized layout and reliable fixation of building electrical circuits are key to ensuring electrical safety. We use Retainer Clips to manage building electrical circuits. Inside the distribution boxes and cabinets of buildings, numerous power lines, control lines, etc. are fixed to cable brackets or trunking using Retainer Clips to prevent cable entanglement and loosening, and to prevent safety hazards such as short circuits or poor contact caused by cable displacement. Retainer Clips securely connect electrical circuits to embedded parts or specialized brackets inside the ceilings and walls of buildings, ensuring that the circuits remain stable during building use. For outdoor electrical equipment wiring, Retainer Clips are used in conjunction with waterproof sleeves to tightly secure the cable to the equipment interface, effectively blocking rainwater and moisture from entering and enhancing the protective performance of the wiring. Practical applications have shown that building projects using Retainer Clips to fix electrical circuits have reduced the incidence of electrical failures by approximately 70%.

3. Retainer Clips assist in the efficient installation of building HVAC systems

The HVAC system is an important component of modern buildings, and its installation quality directly affects the effectiveness of use. We use Retainer Clips to achieve stable installation of HVAC system components. In the refrigerant pipeline connection of the air conditioner, Retainer Clips firmly fix the pipeline and joint to ensure that the refrigerant does not leak and maintain the cooling and heating effect of the air conditioning system. At the flexible connection part of the ventilation duct, Retainer Clips can tightly connect flexible materials such as canvas and rubber to the duct, ensuring the sealing of the ventilation system and absorbing the vibration and noise generated during the operation of the duct. In the centralized heating system of large commercial buildings, Retainer Clips are used to fix hot water pipes, ensuring stable connection even in high temperature and high pressure environments, preventing leakage at pipe interfaces, and ensuring stable operation of the heating system.

4. Retainer Clips enhance the convenience of construction and maintenance in buildings

The convenience of operation is crucial for project progress and cost control during construction and post maintenance processes. Retainer Clips have brought significant convenience to construction and maintenance. At the construction site, using Retainer Clips to fix pipes, cables, and other components does not require complex tools or professional skills, and can be installed with simple operations. Compared to traditional welding or threaded connection methods, the construction efficiency has been improved by about 60%. When building equipment needs maintenance or replacement of components, releasing the Retainer Clips allows for quick disassembly of related pipelines and lines, greatly reducing maintenance time. For example, in the maintenance of building fire protection systems, the use of Retainer Clips to fix fire water pipes and sprinkler heads allows maintenance personnel to easily disassemble and reinstall them, improving maintenance efficiency while also reducing the risk of component damage caused by excessive disassembly.

5. Retainer Clips drive innovative design and functional expansion in the construction industry

With the development of the construction industry towards green and intelligent direction, we use Retainer Clips to achieve innovation and functional expansion in building design. In some new types of prefabricated buildings, Retainer Clips are used to quickly connect pipelines and components in prefabricated components, improving assembly efficiency and connection reliability. In the wiring system of intelligent buildings, Retainer Clips supports modular design, which facilitates users to flexibly adjust the layout of the lines according to their needs and achieve personalized expansion of building functions. In addition, Retainer Clips can also be incorporated into architectural design as decorative elements. By selecting different materials, colors, and shapes of Retainer Clips, unique aesthetic effects can be added to buildings while meeting functional requirements, promoting innovative development in the construction industry.