In the continuous evolution of the electrical product field, we continue to explore innovation, and Flat Springs, with its outstanding characteristics, have gradually become a key element in improving performance and ensuring reliability of many electrical products. Its excellent elasticity, conductivity, and fatigue resistance provide strong support for various electrical products from basic connections to the realization of core functions.

1. Flat Springs stable electrical connection

Reliable electrical connections are the cornerstone of normal operation in various electrical equipment. We frequently use Flat Springs in our design and manufacturing to ensure the stability of the connection. Taking common plugs and sockets as an example, inside the socket, we place Flat Springs behind the metal contacts. When the plug is inserted, Flat Springs tightly compresses the plug pins with its own elasticity, maintaining stable and low resistance electrical contact between the two. Even in complex usage environments such as frequent plugging and vibration, Flat Springs can prevent contact points from loosening by continuously applying pressure, avoiding problems such as electrical sparks, increased resistance, and even equipment short circuits caused by poor contact, ensuring stable power transmission, and safeguarding the safe operation of electrical equipment. In industrial electrical control cabinets, the connection of numerous lines is also facilitated by Flat Springs, ensuring the reliability of the entire system under long-term, high load operation.

2. Flat Springs assists in the operation of electrical switches

Electrical switches play a crucial role in controlling the on/off of electrical circuits in electrical products. We use Flat Springs to optimize switch performance. In a button type switch, Flat Springs serve as elastic elements. When the user presses the button, Flat Springs are compressed and deformed, causing the circuit to close; When the button is released, Flat Springs returns to its original state and disconnects the circuit. This design not only provides clear tactile feedback to the switch, making the user experience better, but more importantly, the high elasticity and fatigue resistance of Flat Springs ensure that the switch can still work stably under long-term frequent operation, effectively extending the service life of the switch. Flat Springs has a wide range of applications, such as household lighting switches and power switches for electronic devices, ensuring the accuracy and reliability of every circuit on/off control.

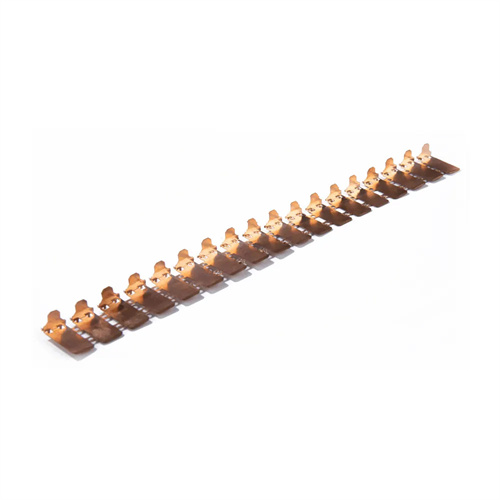

3. Flat Springs optimizes electronic connector performance

Electronic connectors are indispensable for signal and power transmission between various components within electrical products. We use Flat Springs to improve connector performance. In board to board connectors, Flat Springs are designed in a special shape and installed at the connector interface. It can tightly adhere to the metal contacts of the circuit board, compensate for small displacements caused by manufacturing tolerances, thermal expansion and contraction, and maintain stable electrical connections. In high-speed data transmission connectors, the low resistance of Flat Springs effectively reduces losses and interference during signal transmission, ensuring high-speed and accurate data transmission. Flat Springs can be seen everywhere in various connectors inside devices such as smartphones and computers, providing a solid guarantee for efficient and stable data exchange and power supply between various components of the device.

4. Flat Springs is used for shock absorption and protection of electrical products

Electrical products often face adverse environmental factors such as vibration and impact during use. We use Flat Springs to provide shock absorption and protection for electrical products. In some outdoor electrical equipment, such as distribution boxes and street light controllers, Flat Springs are installed between the internal circuit board and the casing of the equipment. When the device is subjected to external vibrations, Flat Springs absorbs the vibration energy through elastic deformation, avoiding damage to electronic components on the circuit board due to vibration and protecting the core components of electrical products. In vehicle electrical equipment, the shock absorption effect of Flat Springs is particularly important. It can effectively reduce the impact of bumps on the equipment during vehicle operation, ensure stable operation of the equipment, and guarantee the normal operation of the vehicle’s electrical system.

5. Flat Springs promotes miniaturization and integration of electrical products

With the development of technology, electrical products are moving towards miniaturization and integration. We found that Flat Springs plays a positive role in this trend. Due to its flat and lightweight appearance, Flat Springs can be flexibly laid out in limited spaces to meet the design requirements of compact internal structures in electrical products. Flat Springs can serve as key elastic and conductive components in miniaturized electrical components such as microsensors and small relays, enabling electrical connections and providing elastic support in confined spaces. Its excellent performance enables electrical products to maintain or even improve performance while reducing their size, injecting vitality into the innovative design of miniaturization and integration of electrical products, and driving the continuous development of the industry.