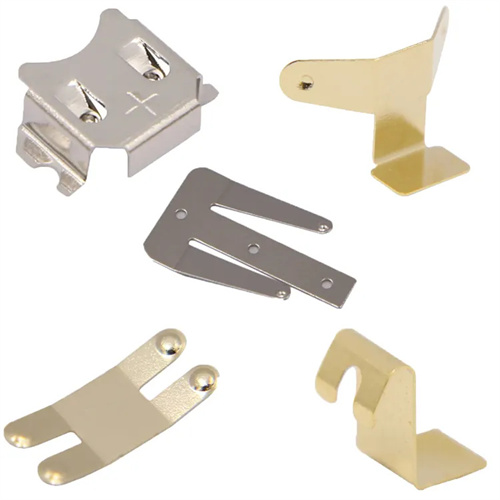

On the road of electrical product manufacturing and optimization, we are always committed to improving product quality and reliability through high-quality components. Although the Retainer Clips have a compact structure, they play an irreplaceable role in the internal component fixation, circuit management, and other key aspects of electrical products due to their excellent fastening, positioning, and protective performance, laying a solid foundation for the stable operation and safe use of electrical products.

1. Retainer Clips achieve stable installation of internal components in electrical products

The stable installation of various core components within electrical products is the foundation for the normal operation of the equipment. We use Retainer Clips to secure key components such as circuit boards, transformers, relays, etc. inside electrical products. Taking the distribution box as an example, many electrical components inside will generate vibration during operation. Using Retainer Clips can firmly fix these components on the installation bracket, prevent component loosening and displacement caused by vibration, and avoid problems such as poor circuit contact. Through precise adaptation of Retainer Clips, we can quickly complete component installation and maintain a stable state during long-term device operation. After testing, the use of Retainer Clips to fix components in the distribution box has reduced the internal component loosening failure rate by about 80%, significantly improving equipment reliability.

2. Retainer Clips ensure orderly fixation and protection of electrical product cables

The cable layout in electrical products needs to be standardized and orderly to ensure stable power transmission and signal transmission. We use Retainer Clips to manage and secure various cables such as power lines, data lines, control lines, etc. for electrical products. In server cabinets, a large number of cables are staggered and distributed. Using Retainer Clips can neatly fix the cables on cable trays or cable racks, avoiding cable entanglement and pulling, and reducing the risk of short circuits or signal interference caused by cable wear. For outdoor electrical equipment, such as power cables in substations, Retainer Clips are used in conjunction with waterproof sleeves to tightly secure the cable to the equipment interface, effectively blocking rainwater and moisture intrusion and enhancing cable protection performance. Practical application shows that using Retainer Clips to fix cables in electrical equipment reduces the incidence of cable related failures by about 75%.

3. Retainer Clips assist in reliable connection of heat dissipation components for electrical products

Heat dissipation is a key factor affecting the performance and lifespan of electrical products, and the stable connection of heat dissipation components is crucial. We use Retainer Clips to achieve reliable installation of electrical product heat sinks, cooling fans, and other components. In high-power frequency converters, the connection between the heat sink and the device body is fastened with Retainer Clips to ensure a tight fit and improve heat transfer efficiency. The elastic clamping characteristics of Retainer Clips not only ensure connection strength, but also adapt to the thermal expansion and contraction changes during equipment operation, preventing loose connections. For the cooling fan, Retainer Clips firmly fix it in the installation position to ensure the stability of the fan during high-speed operation and effectively improve the cooling effect. After testing, it was found that using Retainer Clips to connect the cooling components of the inverter can reduce the temperature of the core components by 6-9 ℃, significantly improving the product’s cooling performance.

4. Retainer Clips enhance the convenience of electrical product assembly and maintenance

The convenience of operation directly affects production efficiency and maintenance costs in the production assembly and post maintenance process of electrical products. Retainer Clips have brought significant convenience to the assembly and maintenance of electrical products. On the production line, using Retainer Clips to fix electrical components does not require complex tools and processes, and can be easily installed with simple operations. Compared to traditional screw fixing methods, assembly efficiency has been improved by about 50%. When the product needs to be repaired or replaced, releasing the Retainer Clips allows for quick disassembly of the relevant components, greatly reducing repair time. For example, in the maintenance of PLC control cabinets, modules fixed with Retainer Clips can be easily disassembled and reinstalled by maintenance personnel, improving maintenance efficiency while reducing the risk of damaging other components due to improper operation.

5. Retainer Clips drive innovative design and functional expansion of electrical products

With the development of electrical products towards intelligence and integration, we use Retainer Clips to achieve innovative design and functional expansion of our products. In modular designed electrical equipment, Retainer Clips are used to quickly connect and disconnect different functional modules, such as combining modules with communication functions with control modules, making it convenient for users to flexibly expand device functions according to their needs. In some new smart electrical products, Retainer Clips can also serve as hidden design elements, achieving component fixation without affecting the simple and beautiful appearance of the product. In addition, by selecting different materials and specifications of Retainer Clips, it is possible to meet the usage needs of electrical products in different environments, providing more possibilities for the innovative development of electrical products.