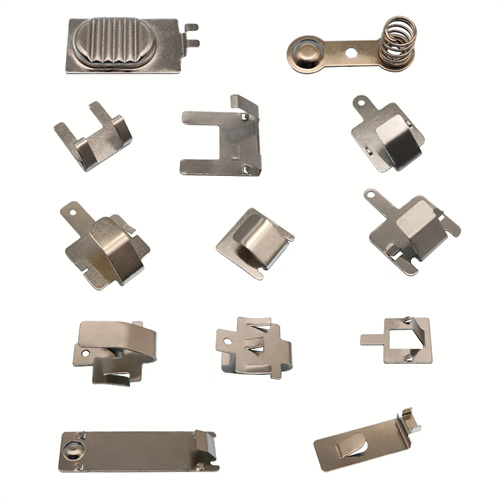

On the path of continuous innovation and progress in hardware tools, we are always committed to exploring high-quality components to enhance the practicality and reliability of our tools. Although the Retainer Clips are compact in size, they play an irreplaceable role in the structural fixation and pipeline connection of hardware tools due to their excellent fastening ability, convenient installation method, and flexible adaptability. They provide a solid guarantee for the efficient use and long-term durability of hardware tools.

1. Retainer Clips ensure stable installation of hardware tool power system components

The power system of hardware tools is its core part, and the stable installation of components is crucial. We use Retainer Clips to secure key components such as motors and transmission systems of electric tools. Taking the electric drill as an example, Retainer Clips are used for the transmission between the motor and the drill bit, which can firmly fix the motor inside the body, avoid the motor displacement caused by the vibration generated by long-term high-speed operation, and prevent transmission system failure. In the connection between the gearbox and the housing of the angle grinder, Retainer Clips can ensure that the gearbox is stable and not loose, ensuring the stability of power transmission. After testing, the use of Retainer Clips to fix power system components in electric tools has reduced the incidence of related failures by about 70%, significantly improving the reliability and service life of the tools.

2. Retainer Clips enable reliable connection of hardware tool piping systems

In hardware tools involving gas and liquid transmission, the sealing and stability of the pipeline system directly affect the effectiveness of tool use. We use Retainer Clips to achieve reliable connection of hardware tool pipelines. At the interface between the pneumatic tool’s trachea and the air pump, Retainer Clips can tightly fix the trachea to prevent air leakage and ensure a stable supply of air source. Whether it is a regular rubber trachea or a high-strength PVC trachea, Retainer Clips can quickly adapt and provide uniform clamping force. Retainer Clips also play a crucial role in the oil pipe connection of hydraulic tools, firmly connecting the oil pipe to hydraulic cylinders, joints, and other parts to prevent hydraulic oil leakage and ensure the normal operation of the tool under high-pressure working conditions. After testing, the use of Retainer Clips to connect hardware tools to the piping system reduced the leakage rate by approximately 80%.

3. Retainer Clips ensure the safety of moving parts of hardware tools

Many components in hardware tools require flexible movement, but at the same time, their safety and stability must also be ensured. We use Retainer Clips to ensure the reliable operation of tool moving parts. At the joints of hand tools such as wrenches and pliers, Retainer Clips can fix the rotating shaft to the handle, jaws, and other components, limiting the range of movement, preventing damage caused by excessive opening and closing of the components, and avoiding finger injuries during use. In some hardware tools with telescopic structures, such as telescopic rods and folding ladders, Retainer Clips can ensure that the telescopic parts are securely locked during use and easy to disassemble during storage, providing users with a safe and convenient operating experience. Through practical use verification, the use of Retainer Clips hardware tools for moving parts has reduced safety hazards by about 75%.

4. Retainer Clips enhance the convenience of hardware tool assembly and maintenance

The convenience of operation directly affects efficiency and cost in the production assembly and post maintenance process of hardware tools. Retainer Clips have brought significant convenience to the assembly and maintenance of hardware tools. On the production line, using Retainer Clips to fix tool components does not require complex tools and professional skills. Installation can be completed with simple operations, and assembly efficiency has been improved by about 60% compared to traditional screw fixation methods. When the tool needs to be repaired or replaced, releasing the Retainer Clips allows for quick disassembly of the relevant components, greatly reducing repair time. For example, when repairing the chain drive system of a chainsaw, the chains and gears fixed with Retainer Clips can be easily disassembled and reinstalled by maintenance personnel, improving repair efficiency while reducing the risk of component damage caused by excessive disassembly of screws.

5. Retainer Clips drive innovative design and functional expansion of hardware tools

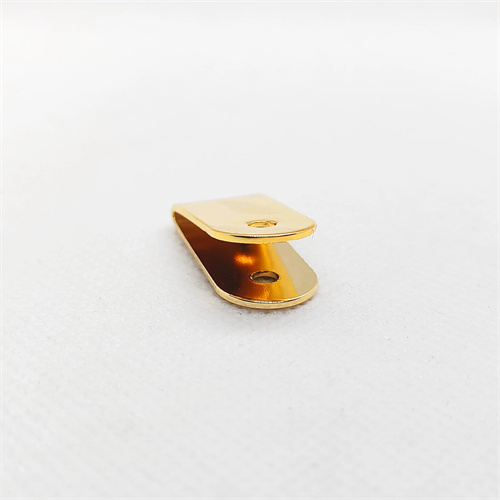

With the innovative development of the hardware tool industry, we utilize Retainer Clips to optimize tool design and expand functionality. In modular design hardware tools, Retainer Clips are used to quickly connect and disassemble different functional modules, such as replaceable power tool drill bit sets, multifunctional combination wrench components, etc., allowing users to freely match according to their needs and expand the scope of tool use. In addition, Retainer Clips can also serve as auxiliary design elements. By selecting Retainer Clips of different materials and specifications, the appearance and ergonomic design of the tool can be improved while meeting functional requirements, injecting new vitality into the innovative development of the hardware tool industry.