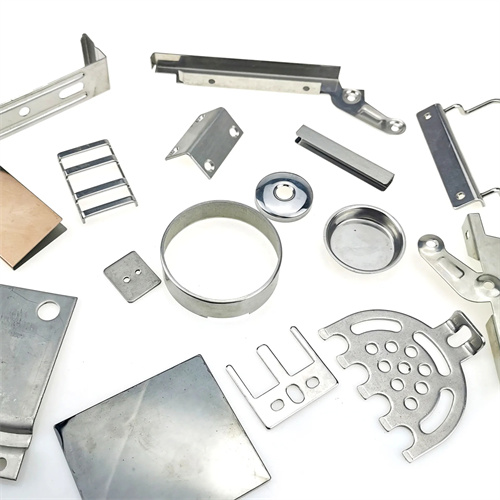

In the wave of constantly innovating in the toy industry, we are always committed to creating toy products that are both fun, safe, and of high quality. Fourslide Multi Slides Parts have become an important force in the field of toy manufacturing due to their high precision, complex shape processing capabilities, and efficient production characteristics. From enhancing the interactive experience of toys to ensuring structural safety, from achieving innovative design to improving production efficiency, Fourslide Multi Slides Parts plays a key role in multiple aspects of the toy industry, bringing children a better quality play experience.

1. Fourslide Multi Slides Parts enhances the interactive function of toys

In toy design, interactivity is a key element that attracts children. We use Fourslide Multi Slides Parts to manufacture various interactive components, adding more fun to toys. Taking catapult toys as an example, the catapult spring and buckle produced through the four slider multi slider process can accurately control the catapult force and angle. The spring manufactured by this process has a stable elastic coefficient, and during the stretching and releasing process, the toy can be ejected from a stable and far distance with a very small error range. After testing, the use of such components in catapult toys has increased the consistency of catapult distance by about 30%, allowing children to better predict and control the toy’s movement trajectory while playing, enhancing the fun and challenge of the game. In some puzzle toys with mechanisms, the metal trigger device manufactured by Fourslide Multi Slides Parts is not only responsive but also durable. Children can trigger the mechanism by pressing, rotating, and other operations, unlocking new game elements and effectively exercising their hands-on and thinking abilities.

2. Fourslide Multi Slides Parts ensure the structural stability of toys

The structural stability of toys is directly related to the safety of children’s use and the service life of toys. We use Fourslide Multi Slides Parts to create sturdy and reliable toy structural components. In the manufacturing of connecting components for building block toys, the metal connecting components produced by the four slider and multi slider process can tightly fit with the building blocks, ensuring that the constructed shape is stable and not easily collapsed. These connectors have extremely high dimensional accuracy and can be adapted to different shapes and specifications of building blocks. The connection strength is about 40% higher than that of ordinary plastic connectors. At the connection parts of the frames of toys such as children’s bicycles and scooters, metal joints made of Fourslide Multi Slides Parts are used, which can withstand large external forces. Even if children shake or collide violently during play, the integrity of the frame structure can be ensured, providing safety protection for children’s outdoor activities.

3. Fourslide Multi Slides Parts assist in innovative design of toys

With the increasing demand for creativity in toys in the market, we utilize Fourslide Multi Slides Parts to achieve unique toy designs. In transformable toys, complex metal joints manufactured through the four slider multi slider process can achieve flexible rotation at multiple angles while maintaining structural stability. For example, a robot transformation toy with joint parts made of Fourslide Multi Slides Parts can easily achieve the transformation from robot form to car form, and the joints can be firmly locked in different forms without loosening or deformation. In some decorative toys with special shapes, the metal decorative parts produced by this process, such as hollow patterns, three-dimensional patterns, etc., add artistic beauty to the toys with their high precision and exquisite details, meeting children’s pursuit of novel toys.

4. Fourslide Multi Slides Parts optimizes the production efficiency of toys

In the large-scale production process of toys, we use Fourslide Multi Slides Parts to improve production efficiency. The multi slider collaborative operation mode of this process can complete multiple complex processes in one machining stroke, which increases production efficiency by about 60% compared to traditional machining processes. Meanwhile, due to the continuous processing of coil materials, the material utilization rate is over 90%, effectively reducing raw material waste. After using the four slider multi slider equipment in the production of toy car wheel axles and body connectors, the hourly output increased from 800 pieces to 1200 pieces, reducing production costs by about 20%. Moreover, its fast mold changing feature enables us to quickly switch the production of different styles of toy parts, respond to market demand changes in a timely manner, and enhance the market competitiveness of the enterprise.

5. Fourslide Multi Slides Parts enhance the durability of toys

Durability is an important indicator for measuring the quality of toys, and we improve the durability of toys through Fourslide Multi Slides Parts. In the manufacturing of easily worn parts such as gears and bearings in toys, metal parts produced using the four slider and multi slider process have undergone special surface treatment to have good wear resistance and corrosion resistance. For example, in the transmission system of electric toy cars, the use of such components extends the service life of gears by about 50%, reduces toy failures caused by component damage, and lowers maintenance costs. In some toy boxes, toy doors, and other structures that require frequent opening and closing, the hinges and buckles manufactured by Fourslide Multi Slides Parts can withstand tens of thousands of opening and closing operations without damage, ensuring that the toys maintain good performance during long-term use.