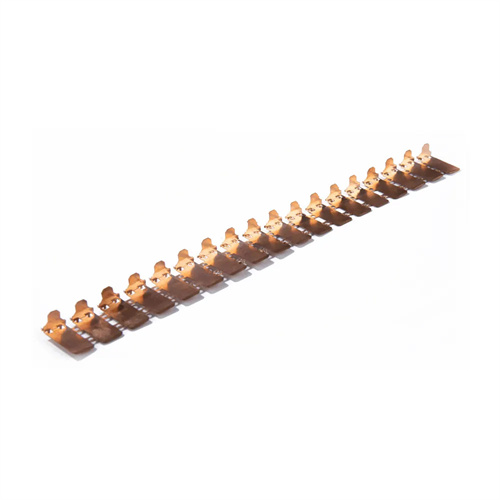

Unrivaled Properties of Beryllium Copper Flat Springs

Beryllium copper flat springs stand out due to their unrivaled combination of properties. At the heart of their superiority lies the exceptional conductivity and springback performance. The high electrical conductivity of beryllium copper allows these flat springs to efficiently transfer electrical signals, making them ideal for applications where electrical connectivity is crucial. Whether in complex electronic circuits or high – tech communication devices, our beryllium copper flat springs ensure reliable signal transmission.

Meanwhile, the remarkable springback performance means that these springs can return to their original shape with precision, even after repeated deflections. This characteristic is a result of the unique molecular structure of beryllium copper, which offers excellent mechanical properties. From small – scale instruments to large – scale industrial machinery, our beryllium copper flat springs maintain their shape and functionality over time, reducing the risk of component failure and ensuring long – term performance.

Diverse Applications Enabled by Unique Features

The superior conductivity and springback performance of our beryllium copper flat springs open the door to a wide range of applications. In the electronics industry, they are used in connectors, switches, and relays. Their high conductivity ensures low electrical resistance, minimizing power loss and enhancing the overall efficiency of electronic devices. For example, in mobile phones and laptops, our flat springs play a vital role in maintaining stable electrical connections, enabling seamless operation of various components.

In the aerospace and defense sectors, the excellent springback performance is highly valued. These springs are incorporated into critical systems such as landing gear mechanisms and cockpit controls. The ability to withstand extreme conditions while maintaining shape and functionality is essential for the safety and reliability of aircraft and military equipment. Additionally, in the automotive industry, beryllium copper flat springs are used in ignition systems and electrical contacts, contributing to the vehicle’s performance and safety.

The Science Behind Production Excellence

Crafting beryllium copper flat springs with such outstanding properties requires a meticulous production process. We start with carefully selected high – purity beryllium copper alloys, which serve as the foundation for our products. Advanced manufacturing techniques, including precision stamping and wire EDM, are employed to shape the springs with utmost accuracy. These processes ensure that the springs meet the exact dimensional requirements, which are crucial for their performance in various applications.

After shaping, the springs undergo a series of heat – treatment processes. Solution annealing and age hardening are carried out to optimize the mechanical and electrical properties of the beryllium copper. This heat – treatment not only enhances the springback performance but also improves the conductivity. Throughout the production process, strict quality control measures are in place, with each spring being inspected at multiple stages to guarantee consistency and reliability.

Rigorous Quality Assurance for Peak Performance

Quality is at the core of our beryllium copper flat springs. We have established a comprehensive quality assurance system that covers every aspect of production, from raw material inspection to the final product. Our quality control team uses state – of – the – art testing equipment to measure the electrical conductivity, mechanical strength, and dimensional accuracy of each spring.

Electrical conductivity is tested using specialized meters to ensure that it meets or exceeds industry standards. Mechanical tests, such as tension and compression tests, are conducted to evaluate the springback performance and durability. Additionally, we perform microscopic inspections to detect any potential flaws in the material or manufacturing process. By adhering to these rigorous quality standards, we can provide our customers with beryllium copper flat springs that deliver consistent and reliable performance in the most demanding environments.

Customization: Tailoring to Your Needs

We understand that different applications have unique requirements, which is why we offer extensive customization services for our beryllium copper flat springs. Our team of experienced engineers works closely with customers to understand their specific needs, whether it’s a particular shape, size, or performance characteristic. Using advanced CAD/CAM technology, we can design and prototype custom – made flat springs in a short period.

From modifying the spring’s curvature to adjusting its thickness and material properties, we have the flexibility to meet a wide range of demands. This customization not only ensures that our flat springs fit perfectly into our customers’ systems but also optimizes their performance. Whether it’s a small – batch order for a specialized project or a large – scale production requirement, we are committed to providing customized solutions that exceed our customers’ expectations.

Comprehensive Customer Support and Service

Our commitment to customers doesn’t end with the delivery of high – quality beryllium copper flat springs. We offer comprehensive customer support and service to ensure a seamless experience throughout the entire process. Our technical support team is available around the clock to answer any questions and provide guidance on product selection, installation, and maintenance.

In case of any issues or concerns, our after – sales service team responds promptly to resolve problems. We also offer training programs for our customers’ engineering and technical staff, helping them better understand the features and applications of our flat springs. Additionally, we maintain a well – stocked inventory to ensure fast delivery times, reducing our customers’ downtime. With our dedicated customer support, we aim to build long – term partnerships based on trust, reliability, and mutual success.