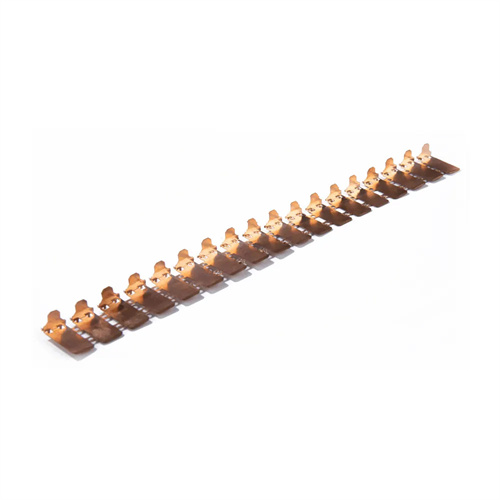

Flat springs, also known as leaf springs or leaf springs, are flat elastic components typically made of metal. They are widely used in various mechanical and electronic products as shock absorbers, buffers, or support components.

The shape and size of Flat Springs can be customized according to specific needs, with common shapes including circular, square, and elongated shapes. They are usually made of materials such as high carbon steel, stainless steel, or alloy steel, and have good elasticity and corrosion resistance. Flat springs generate elasticity through bending and rebound during operation, which can absorb or release energy, providing shock absorption and cushioning.

In addition to its applications in mechanical and electronic products, Flat springs are also widely used in fields such as automotive, aerospace, and medical devices. For example, the leaf spring under the car seat can provide comfortable sitting support while absorbing vibrations and impacts; Leaf springs in the aerospace field are used to provide stable support and shock absorption.

Flat spring clip bracket typically have the following features:

Robust support: provides a stable support structure for the flat spring clamp to ensure that the spring clamp can properly perform the clamping function.

Precise positioning: help to accurately position the spring clip in the desired position for precise clamping.

Variety of materials: can be made from metals (e.g. steel, aluminum) or high-strength plastics to meet different strength, weight and cost requirements.

Applicable to different scenes: applicable to various industrial, mechanical, electronic equipment and other fields, used for fixing cables, pipes, thin plates and other parts.

For example, in automotive manufacture, a flat spring clip bracket may be used to secure wire harnesses in the vehicle; In electronic equipment, it may be used to fix some small components on the circuit board.

When performing heat treatment on Flat Springs, the following points should be noted:

Choose the appropriate heat treatment process: Based on the material type, size, and performance requirements of Flat Springs, choose the appropriate heat treatment process. Different materials may require different heat treatment parameters to achieve optimal results.

Controlling heat treatment parameters: Heating temperature, holding time, and cooling rate have a significant impact on the performance of Flat Spring. Accurate control of these parameters is required to ensure the desired performance is achieved.

Pay attention to the treatment after heat treatment: After heat treatment, Flat Springs may require further surface treatment, such as cleaning, coating, or packaging, to protect it from corrosion or other environmental factors.

When selecting a manufacturer of metal flat springs, there are several key factors to consider:

Production capacity and experience: understand the production scale, equipment advancement and service life of the manufacturer in this field. Experienced and capable manufacturers are often able to meet complex order requirements and guarantee product quality and delivery time.

Quality control system: a reliable manufacturer should have a perfect quality control process, from raw material procurement to finished product inspection, to ensure that each link meets the relevant standards. For example, they may use advanced inspection equipment and strict quality inspection standards to ensure the performance and durability of metal flat springs.

Technical capacity: check whether the manufacturer has advanced production technology and R&D capacity, can customize springs according to special requirements of customers, and provide technical support and solutions.

Material Selection: Premium manufacturers can provide a wide range of high-quality metal materials to meet the performance requirements of springs for different application scenarios.

Customer Comments and Reputation: Review other customers’ comments and feedback on the manufacturer to understand its reputation in the market. Information can be obtained through online comments, industry reports or direct consultation with their past customers.

Cost and price: although price is not the only determinant, it is necessary to ensure that the price provided by the manufacturer is competitive, taking into account product quality and service.

After-sales service: good after-sales service includes timely response to customer problems and complaints, maintenance and warranty of products, etc.