Custom – Engineered Design of Stainless Steel Flat Leaf Springs

Our factory – custom stainless steel flat leaf springs for electronic equipment are a result of meticulous custom – engineering. We understand that each electronic device has unique requirements, and our springs are designed to meet these specific needs precisely. The flat leaf spring design features a sleek and thin profile, which is ideal for the compact and space – constrained environments of modern electronic equipment.

Using advanced CAD/CAM technology, we can customize every aspect of the spring, from its length, width, and thickness to the curvature and number of leaves. This level of customization ensures a perfect fit within various electronic components, whether it’s for a smartphone’s battery holder, a laptop’s hinge mechanism, or a delicate sensor assembly. The custom – engineered design also optimizes the spring’s performance, providing the right amount of force and flexibility to ensure reliable operation and prevent component damage. Our innovative approach to customization sets our stainless steel flat leaf springs apart in the highly competitive electronics market.

Indispensable Role of Flat Leaf Springs in Electronic Equipment

In the world of electronic equipment, our stainless steel flat leaf springs play an indispensable role. These springs are crucial for maintaining the structural integrity and functionality of various components. For example, in portable devices, they act as shock absorbers, protecting sensitive electronic parts from damage caused by accidental drops or vibrations. In addition, they are used to provide the necessary force for holding components in place, ensuring stable electrical connections and preventing loose parts that could disrupt the device’s operation.

In more complex electronic systems, such as servers and networking equipment, our flat leaf springs contribute to heat dissipation by applying even pressure on heat – sinks, enhancing their efficiency. They also play a vital role in mechanisms that require repeated movement, like the opening and closing of CD – ROM drives or the adjustment of display screens. Without our reliable flat leaf springs, the performance, durability, and user experience of electronic equipment would be significantly compromised.

Material and Performance Advantages of Stainless Steel Flat Leaf Springs

We take pride in using high – quality stainless steel to manufacture our flat leaf springs for electronic equipment. Stainless steel offers a multitude of advantages that make it the ideal material for this application. Its excellent corrosion resistance protects the springs from the effects of moisture, humidity, and exposure to various chemicals commonly found in electronic environments, ensuring long – term reliability.

In terms of performance, stainless steel flat leaf springs have high strength – to – weight ratios, allowing them to provide substantial force while remaining lightweight. This is crucial for portable electronic devices where minimizing weight is essential. They also exhibit good fatigue resistance, enabling them to withstand thousands of cycles of compression and extension without losing their shape or performance. These material and performance advantages ensure that our flat leaf springs can operate consistently under the demanding conditions of modern electronic equipment, providing our customers with a product they can trust.

The Meticulous Manufacturing Process of Flat Leaf Springs

The production of our factory – custom stainless steel flat leaf springs is a highly meticulous process that combines advanced manufacturing techniques with strict quality control. It starts with the selection of premium – grade stainless steel alloys, which are carefully inspected for their chemical composition and mechanical properties to ensure they meet our high – quality standards.

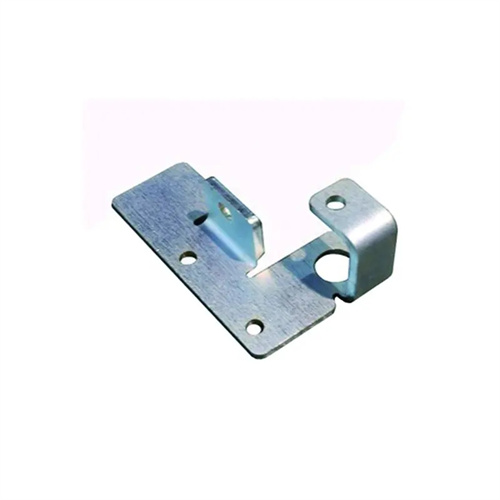

Next, our state – of – the – art manufacturing facilities utilize precision stamping and forming equipment to shape the stainless steel into the desired flat leaf spring configuration. Computer – controlled machines ensure that each spring is produced with exacting tolerances, guaranteeing consistency in size and performance. After forming, the springs undergo heat treatment to optimize their strength, flexibility, and durability. Finally, each spring is thoroughly inspected for dimensional accuracy, surface finish, and mechanical performance before being approved for shipment, ensuring that only the highest – quality products reach our customers.

Rigorous Quality Control of Stainless Steel Flat Leaf Springs

Quality control is at the heart of our manufacturing process for stainless steel flat leaf springs. We have implemented a comprehensive quality control system that covers every stage, from raw material inspection to the final product. Our quality control team uses advanced testing equipment, such as optical comparators, tensile testers, and salt spray chambers, to rigorously test each spring.

During production, in – line inspections are carried out regularly to monitor the manufacturing process and detect any potential issues immediately. After production, each spring undergoes a series of performance tests, including load – testing to verify its force – providing capacity, fatigue – testing to assess its lifespan under repeated use, and corrosion – resistance testing to ensure it can withstand the electronic equipment’s operating environment. By adhering to these strict quality control measures, we can guarantee that our flat leaf springs offer consistent and reliable performance, meeting the high – standards of the electronics industry.

Comprehensive Customer Support for Flat Leaf Springs

We are committed to providing comprehensive customer support for our factory – custom stainless steel flat leaf springs. Our team of experienced engineers and technicians is always available to assist customers with product selection, helping them choose the most suitable spring based on their specific electronic equipment requirements. We offer detailed technical advice on installation, maintenance, and troubleshooting, ensuring that our customers can integrate the springs into their devices smoothly and efficiently.

In addition, our responsive after – sales service team is dedicated to addressing any issues or concerns that customers may encounter. Whether it’s a request for a custom modification, a need for replacement parts, or a question about product performance, we strive to provide prompt and effective solutions. We also offer continuous support through product upgrades and improvements, keeping our customers’ electronic equipment at the forefront of technology. Our goal is to build long – term partnerships with our customers based on trust, reliability, and exceptional service.