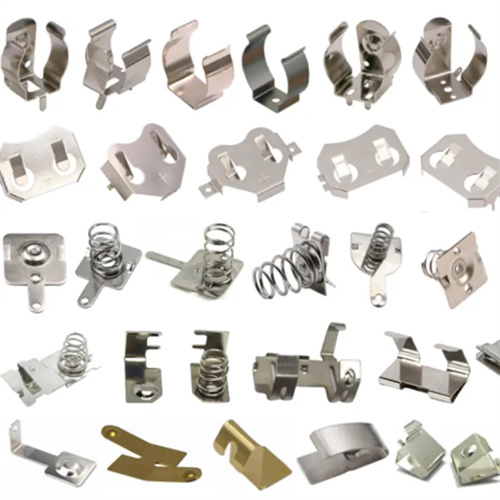

When producing Bend Metal Clip, the fourslide multi-slides have the following significant advantages over other processes:

Better bending shape shaping capacity

The four-slide and multi-slide process can easily achieve complex bend shapes and multi-angle bends, while some traditional processes may be limited in handling complex bends.

For example, a metal clamp with multiple bending points and varying bending angles can be manufactured to meet special design requirements.

Higher accuracy

Provides more accurate dimensional control and bend angle accuracy to ensure consistency with each bend clamp.

This is very important for applications that require high precision fits, such as metal clamps in precision instruments.

High production efficiency

Multiple processes can be performed at the same time, reducing production time and conversion time between processes.

Compared with some step-by-step processes, it can significantly improve the production efficiency and is suitable for large-scale production.

High material utilization rate

Due to precise forming control, raw materials can be used more effectively and waste materials can be reduced.

It has advantages in cost control, especially for expensive metal materials.

Suitable for a variety of materials

It can handle various types of metal materials, including metals with high hardness or special properties.

Some processes may limit the hardness or properties of the material.

Good product quality stability

Highly automated and standardized operation process makes the product quality more stable and reliable.

Reduce quality differences due to human factors or process fluctuations.

In the manufacturing of auto parts, the bending metal clamp produced by four-slider and multi-slider process can meet the strict precision and quality requirements, and the efficient production capacity can meet the large-scale production requirements; In aerospace, this process ensures performance and reliability for high quality, high precision, bent metal clamps.

Fourslide multi-slides parts technology is an advanced stamping process technology that can quickly and efficiently manufacture various complex shaped components through the combined movement of four sliders. Compared to traditional stamping processes, fourslide multi-slides parts technology has higher production efficiency and more precise size control, making it widely used in industries such as automobiles, home appliances, and electronics.

The core of Fourslide technology lies in the combination movement of four sliders, which can achieve precise control of materials and manufacture various shaped components. Compared with traditional stamping processes, fourslide multi-slides parts technology can reduce the number of molds and replacement time, and improve production efficiency. Meanwhile, due to the use of high-precision equipment and control systems in Fourslide technology, precise control of component dimensions can be achieved, improving product quality and performance.

In addition to high precision and efficiency, fourslide multi-slides parts also has the advantage of environmental protection. By precise material control and reducing waste generation, Fourslide multi-slides parts can reduce raw material waste and waste generation, meet the requirements of sustainable development, and also lower prices.

Using the four-slider and multi-slider process to produce pipe clamps has the following advantages and features:

Advantage:

High-precision forming: four-slider and multi-slider process can realize high-precision metal forming, ensure the size and shape accuracy of the pipe clamp, make it closely fit with the pipe and provide reliable clamping force.

Efficient production: multiple processes can be carried out at the same time to improve the production efficiency, suitable for large-scale production of pipe clamps.

High material utilization rate: through accurate die design and process control, waste generation and production cost can be effectively reduced.

Manufacturing of complex shapes: Capable of manufacturing pipe clamps with complex shapes and structures to meet different pipe layout and installation requirements.

Features:

Good consistency: the pipe clamps produced in batches have high consistency and stable and reliable quality.

Strength and durability: after proper process treatment, the produced pipe clamp has good strength and durability and can be used for a long time under severe environment.

Good surface quality: the process can ensure that the pipe clamp surface is smooth without obvious defects, and improve the appearance quality and anti-rust performance.

In the industrial pipeline system, the pipe clamp produced by the four-slider and multi-slider process can firmly fix the pipes of various pipe diameters to ensure the safe operation of the pipeline system; In the cooling system or fuel system of automobile, the pipe clamp produced by this process can adapt to the narrow installation space and provide stable clamping effect.

Fourslide parts usually refer to a series of components manufactured using multi slide technology. This technology can achieve more complex stamping shapes through the combined movement of multiple sliders, further improving the accuracy and production efficiency of stamping.

fourslide multi-slides parts have a wide range of applications and can be used to manufacture various components that require high precision and complex shapes, such as automotive components, household appliance components, electronic components, etc. Due to its high precision and efficient production capacity, fourslide multi-slides parts have been widely applied and recognized in the manufacturing industry.

Manufacturing fourslide multi-slides parts typically requires high-precision manufacturing equipment and process control techniques to ensure that the shape, size, and performance of the components meet the requirements. Meanwhile, in order to achieve efficient production, advanced production management systems and automation technologies are also needed.