Unparalleled Advantages of Fourslide Multi-Slides Parts in Manufacturing

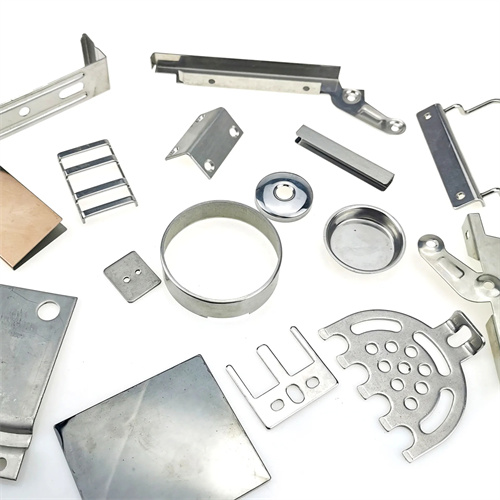

Our Fourslide Multi – Slides Parts offer unparalleled advantages in the manufacturing of stamping cap plates through sheet metal bending. The fourslide multi – slides process stands out as a highly efficient and precise method, enabling us to create complex geometries with ease. Unlike traditional stamping and bending techniques, our multi – slides technology allows for simultaneous operations from multiple directions, which is a game – changer when it comes to forming intricate cap plate designs.

This process not only ensures exceptional dimensional accuracy but also provides outstanding repeatability. With each part produced to exact specifications, we can guarantee consistent quality across large – scale production runs. The ability to perform multiple bends, curves, and folds in a single operation reduces the need for secondary processes, significantly cutting down on production time and costs. For stamping cap plates, where precision and consistency are crucial, our Fourslide Multi – Slides Parts deliver superior results, setting a new standard in the industry.

The Vital Role of Fourslide Multi-Slides Parts in Cap Plate Production

In the production of stamping cap plates, our Fourslide Multi – Slides Parts play a vital role. Cap plates, often used in various industries such as automotive, electronics, and machinery, require precise shaping and bending to fit seamlessly with other components. Our multi – slides parts are instrumental in creating cap plates with accurate dimensions and complex shapes.

During the sheet metal bending process, the fourslide technology allows us to form cap plates with sharp bends, smooth curves, and precise angles. This precision is essential for ensuring proper assembly and functionality. Whether it’s a cap plate for an engine cover in the automotive industry, a protective cover for electronic devices, or a component in heavy machinery, our Fourslide Multi – Slides Parts – produced cap plates provide the necessary structural integrity and aesthetic appeal. By enabling detailed and accurate manufacturing, these parts contribute significantly to the overall quality and performance of the final products.

Material and Performance Benefits of Fourslide Multi-Slides Parts

We take great care in selecting materials for our Fourslide Multi – Slides Parts used in stamping cap plate sheet metal bending. Depending on the application requirements, we choose high – quality sheet metals such as stainless steel, aluminum, and carbon steel. Stainless steel is favored for its excellent corrosion resistance, making it suitable for cap plates exposed to harsh environments or moisture. Aluminum, on the other hand, offers a lightweight yet strong solution, ideal for applications where weight reduction is a priority, such as in aerospace or automotive interiors.

Carbon steel provides high strength and durability, perfect for heavy – duty cap plates in industrial machinery. The fourslide multi – slides process, when combined with these materials, enhances their performance. It allows for precise forming without compromising the material’s mechanical properties, ensuring that the resulting cap plates have excellent strength, fatigue resistance, and dimensional stability. These material and performance benefits make our Fourslide Multi – Slides Parts – produced cap plates reliable and long – lasting in various demanding applications.

The Intricate Manufacturing Process of Fourslide Multi-Slides Parts

The manufacturing process of our Fourslide Multi – Slides Parts for stamping cap plates involves a series of intricate steps. It starts with the careful selection of sheet metal, which is then inspected to ensure it meets our stringent quality standards. The sheet metal is fed into our advanced fourslide machines, which are equipped with precision – engineered dies and tools.

These machines are programmed to perform multiple stamping and bending operations simultaneously, guided by computer – controlled systems. The dies and tools are designed to shape the sheet metal into the desired cap plate geometry with utmost accuracy. After the initial forming, the parts may undergo additional processes such as trimming to remove excess material, deburring to smooth out sharp edges, and surface finishing to enhance their appearance and functionality. Each step of the process is closely monitored and controlled to ensure that the final Fourslide Multi – Slides Parts – produced cap plates are of the highest quality.

Rigorous Quality Control of Fourslide Multi-Slides Parts

Quality control is at the core of our production of Fourslide Multi – Slides Parts for stamping cap plates. We have implemented a comprehensive quality control system that covers every aspect of the manufacturing process. Raw materials are thoroughly tested for their chemical composition, mechanical properties, and surface quality before being used in production.

During the manufacturing process, in – line inspections are carried out regularly to monitor the dimensional accuracy, shape, and surface finish of the parts. Advanced measuring instruments, such as coordinate measuring machines (CMMs) and optical comparators, are used to ensure that each cap plate meets the exact specifications. After production, each part undergoes a series of rigorous tests, including strength testing, bend angle verification, and fatigue testing. Only those Fourslide Multi – Slides Parts – produced cap plates that pass all these tests are approved for shipment, ensuring that our customers receive products of uncompromising quality.

Comprehensive Customer Support for Fourslide Multi – Slides Parts

We are dedicated to providing comprehensive customer support for our Fourslide Multi – Slides Parts used in stamping cap plate sheet metal bending. Our team of experts is available to assist customers throughout the entire process, from the initial design and material selection to after – sales service. We offer technical advice on optimizing cap plate designs for manufacturability, helping customers achieve their desired product performance while minimizing costs.

In case of any issues or concerns, our responsive after – sales service team is ready to provide prompt solutions. Whether it’s a question about product performance, a need for customization, or assistance with installation, we strive to ensure that our customers are completely satisfied with our products and services. We also offer training programs for our customers’ staff, enabling them to better understand and work with our Fourslide Multi – Slides Parts. Our goal is to build long – term partnerships with our customers based on trust, reliability, and mutual success.