Innovative Design of Rubber Lined and R Shape Hose Clamps

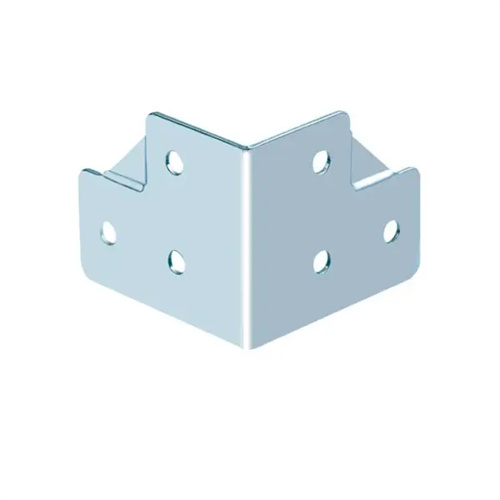

Our P Type Rubber Lined Cable Clamps and Stainless Steel R Shape Hose Clamps combine innovative design elements to meet diverse industrial and commercial needs. The P Type clamps feature a rubber lining that provides a gentle yet secure grip on cables and hoses, preventing damage from abrasion or pressure. This rubber layer acts as a shock absorber, reducing vibration transfer and minimizing the risk of wear and tear, making them ideal for sensitive applications like medical tubing or data cables.

Meanwhile, our Stainless Steel R Shape Hose Clamps are engineered with a robust, curved design that evenly distributes clamping force across the hose. The R shape eliminates sharp edges, ensuring a non-piercing hold that protects soft materials like silicone or rubber hoses. Both designs prioritize functionality and protection, offering solutions that range from heavy-duty industrial use to delicate cable management systems.

Material Advantages for Durability and Protection

The materials used in our hose clamps are chosen for their durability and compatibility with various environments. The rubber lining in P Type clamps is typically made from EPDM or neoprene, offering resistance to oil, heat, and chemicals while maintaining flexibility. This lining not only protects the hose or cable but also provides an anti-slip surface, ensuring a secure fit even under dynamic loads.

For the R Shape clamps, premium stainless steel (such as 304 or 316 grade) forms the core structure, delivering exceptional corrosion resistance and mechanical strength. The stainless steel construction makes them suitable for harsh environments, including marine, automotive, and industrial settings, where exposure to moisture, salt, or high temperatures is common. The combination of rubber and stainless steel creates clamps that balance gentleness with rugged reliability.

Versatile Applications Across Industries

Our hose clamps find versatile use in a wide range of industries. In automotive manufacturing, the R Shape clamps secure radiator hoses and air intake systems, with their stainless steel build enduring under-the-hood heat and vibration. The P Type rubber-lined clamps are popular in electronics and telecommunications for organizing and protecting fiber optic cables or sensitive wiring, where the rubber lining prevents scratching or signal disruption.

In medical devices, both designs excel: the P Type clamps safely secure oxygen tubes or IV lines without damaging delicate materials, while the R Shape clamps provide reliable connections in diagnostic equipment. Industrial applications benefit from their durability, with R Shape clamps used in hydraulic systems and P Type clamps managing power cables in heavy machinery. This versatility makes our clamps essential for any application requiring secure, damage-free hose or cable management.

Precision Manufacturing Process

The manufacturing of our P Type and R Shape hose clamps involves precision engineering to ensure consistent quality. For P Type clamps, we use injection molding to create the rubber lining, ensuring a perfect fit within the metal housing. The stainless steel components are formed using CNC stamping or casting, achieving tight tolerances and smooth edges to prevent hose damage.

R Shape clamps undergo a meticulous bending and shaping process to achieve their curved profile, with each clamp tested for dimensional accuracy using optical comparators. After assembly, both designs undergo rigorous quality checks, including load testing to verify clamping force and compatibility tests to ensure the rubber lining adheres securely to the metal frame. This attention to detail guarantees that every clamp meets our high standards for performance and reliability.

Rigorous Quality Control Measures

Quality control is integral to our production process. We start by testing raw materials: rubber linings are evaluated for elasticity, chemical resistance, and temperature tolerance, while stainless steel is tested for tensile strength and corrosion resistance using salt spray tests (ASTM B117). During manufacturing, in-line inspections monitor the alignment of rubber linings and the precision of R Shape curves.

Final inspections include functional tests to ensure clamps provide adequate tension without damaging hoses or cables. For R Shape clamps, we simulate high-pressure scenarios to validate their structural integrity, while P Type clamps are tested for vibration resistance to ensure the rubber lining remains effective over time. These measures ensure that our hose clamps deliver consistent performance, even in the most demanding applications.

Customer-Centric Solutions and Support

We pride ourselves on delivering customer-centric solutions, offering customization for both designs. Whether clients need specific clamp sizes, rubber compounds, or stainless steel grades, our team collaborates to meet unique requirements. For example, we can provide FDA-approved rubber linings for medical applications or marine-grade stainless steel for offshore use.

Our support extends beyond production: we offer technical guidance on clamp selection, installation, and maintenance. Our after-sales team promptly addresses inquiries, providing replacement parts or troubleshooting assistance as needed. By prioritizing flexibility and reliability, we aim to be more than a supplier—we strive to be a partner in our clients’ success, ensuring their projects benefit from the best hose and cable clamping solutions available.