Robust Design of High-Pressure T-Bolt Hose Clamps

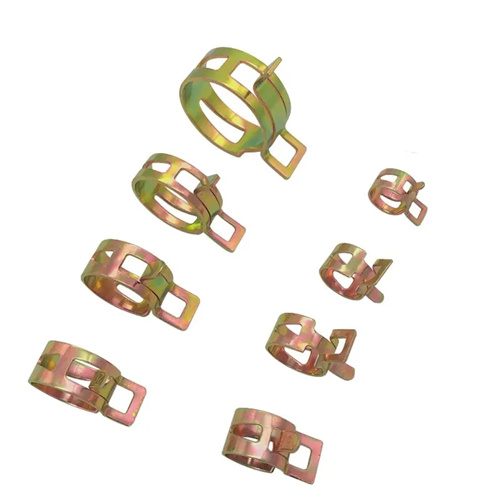

Our T-Bolt Hose Clamps are meticulously engineered with a robust design, tailored specifically for high-pressure applications reaching up to 500 PSI. The distinctive T-bolt mechanism is the cornerstone of this design, offering unparalleled clamping force adjustment. Unlike conventional hose clamps, the T-bolt can be tightened with a standard wrench, allowing users to exert precise torque and achieve a secure, leak-proof seal even under extreme pressure.

The heavy-duty band of our hose clamps is constructed to distribute pressure evenly across the hose, preventing deformation and ensuring long-lasting performance. The T-bolt’s unique shape provides a larger contact surface, minimizing the risk of slippage during tightening. Additionally, the clamp’s body is designed with reinforced edges to withstand the high forces generated at 500 PSI, making it a reliable choice for critical high-pressure systems. This robust design guarantees that our T-Bolt Hose Clamps can endure the harshest operating conditions without compromising on safety or functionality.

Crucial Role in High-Pressure Industrial Systems

In high-pressure industrial systems, our T-Bolt Hose Clamps play a crucial and irreplaceable role. Industries such as manufacturing, oil and gas, and construction rely on hydraulic and pneumatic systems that operate at high pressures. Any failure in hose connections within these systems can lead to significant disruptions, costly downtime, and even safety hazards.

For instance, in hydraulic presses used for metal forming, where pressures can rapidly reach 500 PSI, our T-Bolt Hose Clamps ensure that hoses remain firmly attached, enabling seamless operation. In the oil and gas sector, they are employed to secure hoses in high-pressure pumping and extraction equipment, preventing leaks of valuable fluids and hazardous materials. In construction machinery, these clamps maintain the integrity of hydraulic hoses in excavators and cranes, allowing for efficient and reliable operation. Their ability to withstand high pressures makes them an essential component for maintaining the safety and efficiency of high-pressure industrial systems.

Material Superiority of T-Bolt Hose Clamps

We take pride in the superior materials used to manufacture our T-Bolt Hose Clamps, which are carefully selected to meet the demands of high-pressure applications. The bands are typically crafted from high-grade stainless steel or alloy steel, known for their exceptional strength, corrosion resistance, and fatigue endurance. These materials can withstand the intense mechanical stress and pressure fluctuations associated with 500 PSI environments, ensuring that the clamps do not deform or break under load.

The T-bolts and nuts are made from durable alloys with high tensile strength, capable of withstanding the torque applied during tightening without stripping or fracturing. Some models feature additional surface treatments, such as galvanization or plating, to enhance corrosion resistance and extend the lifespan of the clamps in harsh operating conditions. The combination of these high-quality materials gives our T-Bolt Hose Clamps the edge in performance, reliability, and longevity, making them the preferred choice for high-pressure applications across various industries.

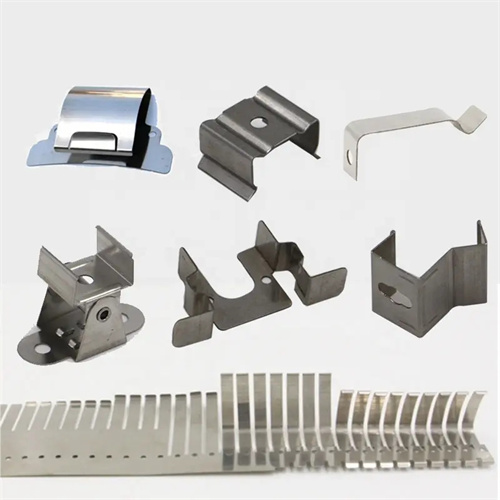

Meticulous Manufacturing Process of T-Bolt Hose Clamps

The manufacturing process of our T-Bolt Hose Clamps is a meticulous endeavor that combines advanced technology and skilled craftsmanship. It commences with the careful sourcing of premium raw materials, which undergo rigorous testing to ensure their quality and compliance with industry standards. The bands are precision-formed using state-of-the-art stamping and rolling machines, guaranteeing consistent dimensions and a smooth finish.

The T-bolts and nuts are manufactured with high precision using CNC machining, ensuring accurate threading and optimal functionality. Each component is subjected to multiple quality inspections during the production process to ensure dimensional accuracy and proper assembly. After fabrication, the hose clamps are assembled with great care, followed by a series of comprehensive tests. These include pressure testing to simulate real-world high-pressure conditions, torque testing to verify the clamping force, and fatigue testing to assess long-term durability. This meticulous process ensures that every T-Bolt Hose Clamp leaving our facility meets the highest standards of quality and performance.

Rigorous Quality Control of T-Bolt Hose Clamps

Quality control is of utmost importance in the production of our T-Bolt Hose Clamps for high-pressure applications. We have implemented a comprehensive quality control system that encompasses every stage of the manufacturing process, from raw material inspection to the final product. Our quality control team utilizes advanced testing equipment, such as pressure chambers, torque testers, and coordinate measuring machines, to ensure the integrity of each hose clamp.

Raw materials are tested for their chemical composition, mechanical properties, and corrosion resistance. During the manufacturing process, in-line inspections are carried out regularly to monitor the production quality, including the precision of the T-bolt threading and the uniformity of the band. After production, each hose clamp undergoes a series of stringent tests, including a 500 PSI pressure test for an extended period to verify its leak-proof capabilities and a cyclic fatigue test to simulate long-term usage. Only hose clamps that pass all these rigorous tests are approved for shipment, ensuring that our customers receive products they can rely on in high-pressure environments.

Comprehensive Customer Support for T-Bolt Hose Clamps

We are dedicated to providing comprehensive customer support for our T-Bolt Hose Clamps. Our team of experts is readily available to assist customers throughout the entire process, from the initial product selection to after-sales service. We offer detailed technical advice on choosing the right type of hose clamp for specific high-pressure applications, taking into account factors such as hose size, fluid type, operating temperature, and pressure requirements.

In case of any issues or concerns, our responsive after-sales service team is committed to providing prompt solutions. Whether it’s a question about product performance, a need for replacement parts, or assistance with installation and maintenance, we strive to ensure that our customers are completely satisfied with our products and services. We also offer training programs for our customers’ technicians, equipping them with the knowledge and skills to install and maintain our T-Bolt Hose Clamps effectively. Our goal is to build long-term partnerships with our customers based on trust, reliability, and exceptional support in high-pressure applications.