The Distinct Advantage of OEM-Approved Retainer Clips

Our automotive retainer clips hold a significant edge with their OEM approval, a mark of exceptional quality and reliability. Achieving OEM approval demands stringent testing and strict compliance with the most exacting industry benchmarks. This endorsement confirms that our retainer clips precisely meet the specifications and performance requirements set by original equipment manufacturers for both interior and exterior trim applications.

For automotive manufacturers, using our OEM-approved retainer clips means seamless integration into existing production lines, eliminating concerns about compatibility issues. In the aftermarket, these clips offer assurance to repair shops and car enthusiasts, as they provide replacement parts that match the original quality. Our retainer clips, with their OEM – approved status, not only ensure a secure fit but also contribute to the overall aesthetics and functionality of vehicles, making them a trusted choice in the automotive industry.

Crucial Role of Retainer Clips in Interior Trim

In automotive interior trim, our retainer clips play a crucial and multifaceted role. The interior of a vehicle demands a combination of functionality, comfort, and aesthetics, and our retainer clips contribute significantly to all these aspects. They are used to secure various components such as door panels, dashboard trims, center consoles, and interior moldings.

These clips ensure that each part fits snugly, preventing rattling or vibrations that could disrupt the driving experience. Their precise design allows for easy installation and removal during manufacturing or maintenance, reducing assembly time and costs. Moreover, the low-profile and unobtrusive nature of our retainer clips ensures that they do not detract from the interior’s sleek appearance. By providing a secure and reliable hold, our retainer clips enhance the overall quality and durability of automotive interior trim.

Essential Function of Retainer Clips in Exterior Trim

When it comes to automotive exterior trim, our retainer clips are equally essential for maintaining the vehicle’s appearance and performance. Exterior trim components, such as fender liners, bumper covers, side moldings, and hood seals, are exposed to various environmental factors like wind, rain, temperature fluctuations, and road debris.

Our retainer clips are engineered to withstand these harsh conditions, ensuring that exterior trim parts remain firmly in place. They provide a secure connection that resists vibrations and impacts during vehicle operation, preventing components from loosening or detaching. This not only safeguards the vehicle’s aesthetic appeal but also protects underlying components from damage. Whether it’s a high-performance sports car or a rugged SUV, our retainer clips contribute to the vehicle’s aerodynamics and structural integrity by keeping exterior trim securely attached.

Material and Design Excellence of Retainer Clips

We take pride in the materials and design of our automotive retainer clips, which are carefully selected and crafted to meet the unique demands of the automotive industry. For interior clips, we use high-quality plastics that are lightweight, durable, and resistant to fading and cracking caused by exposure to sunlight and heat. These materials also offer excellent noise-dampening properties, reducing unwanted sounds within the vehicle cabin.

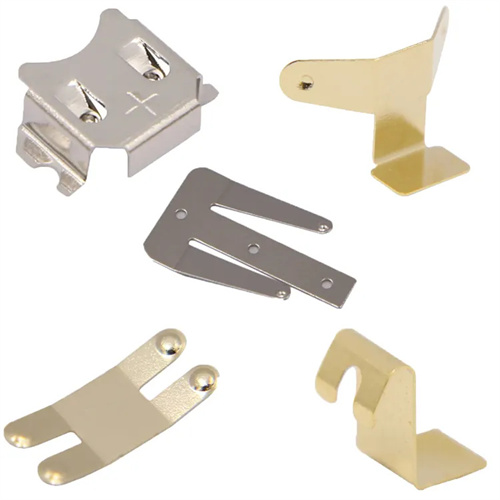

Exterior retainer clips are often made from robust materials such as reinforced nylon or stainless steel. Reinforced nylon provides strength and flexibility, allowing the clips to withstand the rigors of outdoor use while maintaining a secure grip. Stainless steel clips, on the other hand, offer superior corrosion resistance, making them ideal for parts exposed to moisture and salt, such as those in coastal areas. The design of our clips features precise geometries and snap-fit mechanisms, ensuring a secure hold while facilitating easy installation and removal.

Meticulous Manufacturing Process of Retainer Clips

The production of our automotive retainer clips involves a meticulous manufacturing process that combines advanced technology and strict quality control. We start by sourcing premium raw materials that meet our high standards for performance and durability. The materials are then processed using state-of-the-art injection molding machines for plastic clips or precision stamping equipment for metal clips.

Each step of the manufacturing process is closely monitored to ensure dimensional accuracy and consistent quality. For plastic clips, factors such as melt temperature, injection pressure, and cooling time are precisely controlled to achieve the desired shape and strength. Metal clips undergo processes like cutting, bending, and finishing with utmost precision. After production, every retainer clip is thoroughly inspected for defects, including cracks, deformities, or improper sizing. This meticulous process guarantees that our retainer clips are of the highest quality and ready to meet the demands of automotive applications.

Comprehensive Customer Support for Retainer Clips

We are committed to providing comprehensive customer support for our automotive retainer clips. Our team of experts is available to assist customers throughout the entire process, from the initial product selection to after-sales service. We offer detailed technical advice on choosing the right type of retainer clip for specific interior and exterior trim applications, taking into account factors such as vehicle make and model, component size, and environmental conditions.

In case of any issues or concerns, our responsive after-sales service team is ready to provide prompt solutions. Whether it’s a question about product performance, a need for replacement parts, or assistance with installation, we strive to ensure that our customers are completely satisfied with our products and services. We also collaborate closely with automotive manufacturers and suppliers to offer customized solutions if required. Our goal is to build long-term partnerships with our customers based on trust, reliability, and exceptional support in the automotive industry.