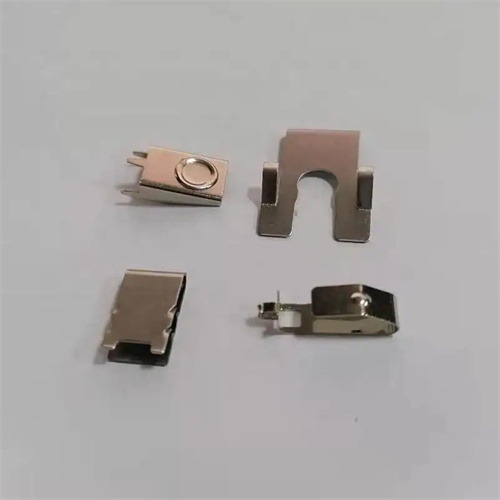

Innovative Design of Custom Retainer Clips

Our Custom Galvanized Metal Stamping Spring Steel Retaining Clips are the result of innovative design, tailored to meet the diverse and specific needs of our clients. The unique combination of galvanized metal stamping and spring steel gives these retainer clips a design that offers both strength and flexibility. The spring steel component allows for a secure grip on the objects it holds, adapting to slight variations in size and shape while maintaining a firm hold.

The galvanized metal stamping provides a robust outer structure, with precise shapes and dimensions achieved through advanced stamping techniques. This design ensures that the clips can be customized to fit various applications, whether it’s securing hoses in automotive engines or holding components in industrial machinery. The clips’ design also takes into account ease of installation and removal, making them highly practical for both assembly lines and maintenance tasks.

Material Advantages of Retainer Clips

We take pride in the materials used for our retainer clips, which are carefully selected to provide optimal performance. Spring steel, known for its high elasticity and fatigue resistance, forms the core of the clip’s functionality. It can endure repeated stress and deformation without losing its shape or clamping force, making it ideal for applications where a consistent and reliable hold is required over an extended period.

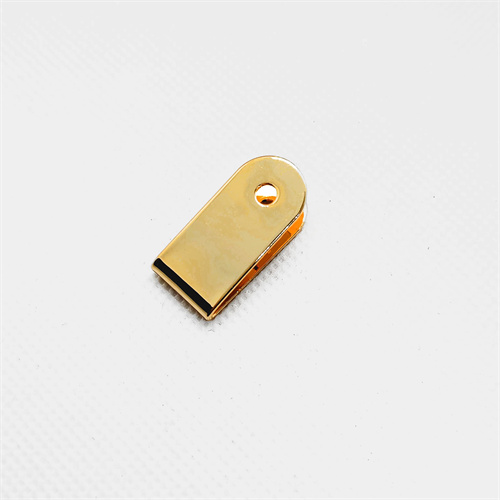

The galvanized metal coating on the stamped parts offers excellent corrosion resistance. Galvanization involves applying a layer of zinc to the metal surface, creating a protective barrier against moisture, rust, and environmental elements. This makes our retainer clips suitable for use in harsh environments, such as outdoor installations, marine applications, or areas with high humidity. The combination of spring steel’s strength and the galvanized metal’s durability ensures that our retainer clips can withstand the rigors of various working conditions.

Versatile Applications of Retainer Clips

Our Custom Galvanized Metal Stamping Spring Steel Retaining Clips find versatile applications across multiple industries. In the automotive sector, they are used to secure fuel lines, electrical cables, and air intake hoses, ensuring that components remain in place during the vehicle’s operation and are protected from vibrations and movement. In the aerospace industry, where precision and reliability are crucial, these clips are employed to hold critical parts in place, contributing to the safety and functionality of aircraft.

For industrial machinery, our retainer clips are essential for fastening components, preventing them from loosening during operation and reducing the risk of equipment failure. They are also widely used in the electronics industry for organizing and securing wires and connectors in circuit boards and devices. From large-scale manufacturing to intricate electronic assembly, our retainer clips offer a reliable solution for a wide range of fastening needs.

Meticulous Manufacturing Process of Retainer Clips

The production of our Custom Galvanized Metal Stamping Spring Steel Retaining Clips involves a meticulous manufacturing process that combines advanced technology with skilled craftsmanship. It starts with the selection of high-quality spring steel and metal sheets for stamping. These raw materials are carefully inspected for their chemical composition, mechanical properties, and surface quality to ensure they meet our strict standards.

The metal stamping process uses state-of-the-art presses and precision dies to shape the metal into the desired clip design with high accuracy. After stamping, the clips undergo galvanization treatment, where a layer of zinc is applied through either hot-dip or electroplating methods. The spring steel components are then formed and heat-treated to achieve the optimal level of elasticity and strength. Finally, each retainer clip is assembled, inspected, and tested for functionality before being approved for shipment.

Rigorous Quality Control of Retainer Clips

Quality control is at the heart of our production of retainer clips. We have implemented a comprehensive quality control system that monitors every stage of the manufacturing process, from raw material inspection to the final product. Our quality control team uses a variety of advanced testing equipment and techniques to ensure the integrity of each clip.

Raw materials are tested for tensile strength, hardness, and corrosion resistance. During the manufacturing process, in-line inspections are carried out regularly to monitor the dimensional accuracy, surface finish, and assembly quality of the clips. After production, each retainer clip undergoes a series of performance tests, including load-bearing tests to verify its clamping force, fatigue tests to assess its durability under repeated use, and salt spray tests to evaluate the effectiveness of the galvanized coating. Only clips that pass all these rigorous tests are approved for delivery to our customers.

Comprehensive Customer Support for Retainer Clips

We are committed to providing comprehensive customer support for our Custom Galvanized Metal Stamping Spring Steel Retaining Clips. Our team of experts is available to assist customers throughout the entire process, from the initial design consultation to after-sales service. We work closely with clients to understand their specific requirements and provide customized solutions, whether it’s modifying the clip’s shape, size, or material.

In case of any issues or concerns, our responsive after-sales service team is ready to provide prompt solutions. Whether it’s a question about product performance, a need for replacement parts, or assistance with installation, we strive to ensure that our customers are completely satisfied with our products and services. We also offer technical support and training to help our customers make the best use of our retainer clips, aiming to build long-term partnerships based on trust and reliability.