Precision Design of Electronics Retainer Clips

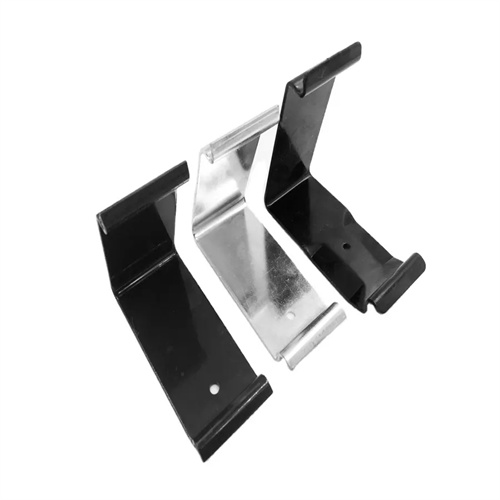

Our electronics retainer clips are engineered with a precision design specifically tailored for PCB and component securement. Recognizing the intricate nature of electronic assemblies, these clips feature ultra-thin profiles and compact shapes to fit within the tight spaces of printed circuit boards (PCBs). The design incorporates fine-tuned clamping mechanisms that provide a secure hold on components without applying excessive pressure, preventing damage to delicate electronic parts.

The clips’ geometry is optimized for easy insertion and removal during the assembly and maintenance processes. Some models are designed with snap-fit features, allowing for quick installation on PCBs, while others have adjustable tension settings to accommodate different component sizes and weights. This precision design not only ensures the stability of components during the operation of electronic devices but also enhances the efficiency of the assembly process, making our electronics retainer clips an essential tool for electronics manufacturers.

Crucial Role in PCB and Component Securement

In the realm of electronics, our retainer clips play a crucial and irreplaceable role in securing PCBs and components. PCBs are the backbone of electronic devices, housing numerous components that need to be firmly held in place to ensure proper electrical connections and prevent failures caused by movement or vibration. Our retainer clips provide a reliable solution by firmly fastening components such as integrated circuits, capacitors, resistors, and connectors to the PCB.

During the transportation and operation of electronic devices, components are often subjected to shocks, vibrations, and temperature changes. Our retainer clips withstand these external forces, maintaining the integrity of the PCB assembly. By keeping components securely in position, they prevent issues like loose connections, short circuits, and component displacement, ultimately contributing to the overall reliability and lifespan of electronic products.

Material Excellence of Electronics Retainer Clips

We take great care in selecting materials for our electronics retainer clips to ensure optimal performance in electronic applications. The clips are typically made from high-quality engineering plastics, such as nylon, polypropylene, or PEEK (Polyether Ether Ketone). These materials offer excellent electrical insulation properties, preventing unwanted electrical conduction between components and the PCB.

In addition to insulation, engineering plastics provide good mechanical strength and flexibility. They can endure the stress of clamping components without breaking or deforming over time. Some clips may also incorporate metal inserts or coatings for enhanced strength and heat dissipation capabilities. Moreover, these materials are resistant to chemicals, moisture, and UV radiation, making our retainer clips suitable for use in a wide range of environmental conditions, from consumer electronics to industrial control systems.

Meticulous Manufacturing Process of Retainer Clips

The production of our electronics retainer clips involves a meticulous manufacturing process that combines advanced technology with strict quality control. We start by sourcing premium raw materials that meet the highest standards for electrical and mechanical properties. These materials are then processed using state-of-the-art injection molding machines, which allow for the creation of complex and precise clip geometries with high accuracy.

Each step of the manufacturing process is closely monitored to ensure dimensional consistency and surface finish quality. The molds used in injection molding are designed with precision to achieve the desired clip shape and features. After molding, the clips undergo a series of post-processing steps, such as trimming, deburring, and cleaning, to remove any excess material and ensure a smooth surface. Finally, every retainer clip is inspected for defects before it leaves our facility.

Rigorous Quality Control of Retainer Clips

Quality control is at the core of our production of electronics retainer clips. We have implemented a comprehensive quality control system that covers every aspect of the manufacturing process, from raw material inspection to the final product. Our quality control team uses a variety of advanced testing equipment and techniques to ensure the integrity of each clip.

Raw materials are tested for their electrical insulation resistance, mechanical strength, and chemical compatibility. During the manufacturing process, in-line inspections are carried out regularly to monitor the dimensional accuracy, flash formation, and proper filling of the injection-molded parts. After production, each retainer clip undergoes a series of performance tests, including clamping force tests, fatigue tests, and heat resistance tests. Only clips that pass all these rigorous tests are approved for shipment, ensuring that our customers receive reliable products for their electronic assemblies.

Comprehensive Customer Support for Retainer Clips

We are committed to providing comprehensive customer support for our electronics retainer clips. Our team of experts is available to assist customers throughout the entire process, from the initial product selection to after-sales service. We offer detailed technical advice on choosing the right type of retainer clip for specific PCB and component applications, taking into account factors such as component size, weight, operating temperature, and environmental conditions.

In case of any issues or concerns, our responsive after-sales service team is ready to provide prompt solutions. Whether it’s a question about product performance, a need for replacement parts, or assistance with installation, we strive to ensure that our customers are completely satisfied with our products and services. We also collaborate with customers on custom projects, offering tailored solutions to meet unique requirements. Our goal is to build long-term partnerships with our customers based on trust, reliability, and exceptional support in the electronics industry.