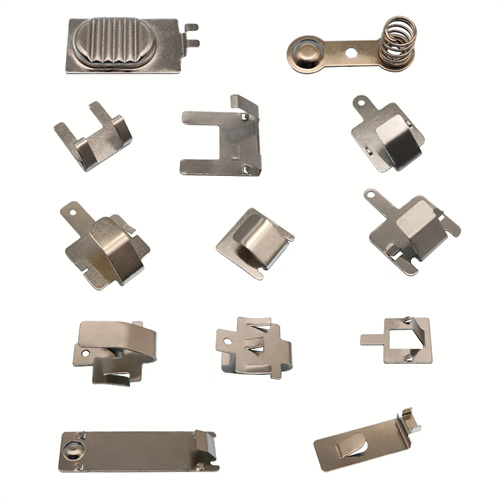

Ingenious Design of U-shaped Carbon Steel Retainer Clips

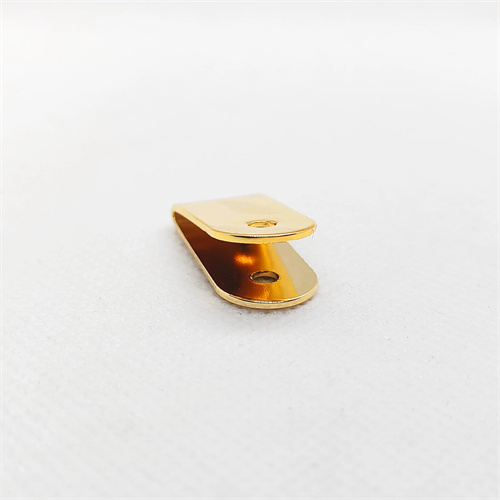

Our Fastener Fixing Speed Nut Clip, crafted as U-shaped Carbon Steel Spring Clip Nuts, boasts an ingenious design that sets it apart in the realm of fasteners. The U-shape provides a versatile and secure grip, allowing for easy attachment to a variety of objects, from pipes and rods to structural components. This shape evenly distributes the clamping force, ensuring a stable hold without causing damage to the fastened item.

The integrated spring mechanism in these retainer clips offers an added layer of functionality. It enables quick and effortless installation, as the spring’s elasticity allows the clip to expand and contract, fitting snugly onto the target object. The speed nut feature further enhances the convenience, allowing for rapid tightening and loosening with minimal effort. Whether used in assembly lines or maintenance tasks, the design of our U-shaped carbon steel retainer clips maximizes efficiency and reliability.

Material Advantages of Carbon Steel Retainer Clips

We take pride in the choice of carbon steel for manufacturing our retainer clips, as it offers numerous advantages crucial for various applications. Carbon steel provides excellent mechanical strength, enabling our clips to withstand heavy loads and high levels of stress. This makes them ideal for industrial settings where robust fastening solutions are required to secure machinery parts or structural elements.

The durability of carbon steel ensures that our retainer clips can endure harsh environmental conditions, including exposure to moisture, dust, and vibrations. Additionally, carbon steel can be heat-treated to achieve specific hardness levels, optimizing the clips’ performance based on the application’s needs. With proper surface treatments, such as galvanization or painting, our carbon steel retainer clips also gain enhanced corrosion resistance, extending their lifespan and maintaining their functionality over time.

Diverse Applications of Retainer Clips

Our U-shaped Carbon Steel Spring Clip Nuts find diverse applications across multiple industries. In the automotive sector, they are used to secure hoses, cables, and brackets, ensuring that components remain in place during the vehicle’s operation and are protected from vibrations and movement. In construction, these retainer clips play a vital role in fastening pipes, electrical conduits, and structural supports, contributing to the stability and safety of buildings and infrastructure.

For manufacturing plants, our clips are essential for holding various parts in place during assembly, improving production efficiency and product quality. They are also widely utilized in the furniture industry to attach legs, panels, and other components, providing a secure and reliable connection. From large-scale industrial projects to small-scale DIY tasks, our retainer clips offer a practical and versatile fastening solution.

Meticulous Manufacturing Process of Retainer Clips

The production of our Fastener Fixing Speed Nut Clip is a meticulous process that combines advanced technology with strict quality control. We begin by sourcing high-grade carbon steel raw materials, which are carefully inspected for their chemical composition and mechanical properties to meet our stringent standards.

Using state-of-the-art stamping and forming equipment, we shape the carbon steel into the precise U-shape of the retainer clip. The spring mechanism and speed nut features are integrated during this process with high precision, ensuring smooth operation. After forming, the clips undergo a series of surface treatments, such as cleaning, heat treatment, and coating application, to enhance their performance and appearance. Finally, each retainer clip is thoroughly tested for functionality, strength, and durability before it leaves our facility.

Rigorous Quality Control of Retainer Clips

Quality control is at the heart of our production of U-shaped Carbon Steel Spring Clip Nuts. We have implemented a comprehensive quality control system that monitors every stage of the manufacturing process, from raw material inspection to the final product. Our quality control team uses a variety of advanced testing equipment and techniques to ensure the integrity of each clip.

Raw materials are tested for tensile strength, hardness, and chemical composition. During the manufacturing process, in-line inspections are carried out regularly to monitor the dimensional accuracy, surface finish, and proper assembly of the clips. After production, each retainer clip undergoes a series of performance tests, including load-bearing tests to verify its holding capacity, fatigue tests to assess its durability under repeated use, and corrosion resistance tests. Only clips that pass all these rigorous tests are approved for shipment, ensuring that our customers receive reliable and high-quality products.

Comprehensive Customer Support for Retainer Clips

We are committed to providing comprehensive customer support for our Fastener Fixing Speed Nut Clip. Our team of experts is available to assist customers throughout the entire process, from the initial product selection to after-sales service. We offer detailed technical advice on choosing the right type of retainer clip for specific applications, taking into account factors such as the size and weight of the objects to be fastened, the operating environment, and the required level of strength.

In case of any issues or concerns, our responsive after-sales service team is ready to provide prompt solutions. Whether it’s a question about product performance, a need for replacement parts, or assistance with installation, we strive to ensure that our customers are completely satisfied with our products and services. We also offer customization services for customers with unique requirements, ensuring that our retainer clips meet their specific needs. Our goal is to build long-term partnerships with our customers based on trust, reliability, and exceptional support.