Intelligent Design of HVAC Retainer Clips

Our HVAC Retainer Clips are engineered with an intelligent design that addresses the specific challenges of ductwork and panel fastening. These clips feature a unique shape and structure that allows for a secure and snug fit on various HVAC components. For ductwork, the clips are designed to wrap around pipes and fittings, distributing clamping force evenly to prevent air leaks and ensure efficient airflow.

In the case of panel fastening, the clips have a streamlined profile that enables them to hold panels firmly in place without protruding or interfering with the system’s operation. Some models incorporate adjustable mechanisms, allowing installers to customize the tightness according to the thickness and material of the ducts or panels. This intelligent design not only simplifies the installation process but also enhances the overall performance and durability of HVAC systems, making our retainer clips an essential choice for professionals in the industry.

Indispensable Role in Ductwork and Panel Fastening

In HVAC systems, our retainer clips play an indispensable role in maintaining the integrity and functionality of ductwork and panels. Ducts are responsible for transporting heated or cooled air throughout buildings, and any leakage can lead to significant energy losses and reduced comfort levels. Our retainer clips ensure that duct joints are tightly sealed, preventing air from escaping and optimizing the system’s efficiency.

For panels, which house critical HVAC components such as blowers, filters, and heat exchangers, a secure fastening is crucial. Our retainer clips keep these panels firmly attached, protecting the internal components from damage caused by vibrations and external forces. By providing reliable fastening solutions, our clips contribute to the smooth operation of HVAC systems, reducing the risk of breakdowns and minimizing maintenance requirements.

Material Excellence of HVAC Retainer Clips

We take great care in selecting materials for our HVAC Retainer Clips to ensure they can withstand the demanding conditions of HVAC environments. The clips are typically made from high-quality materials such as galvanized steel, stainless steel, or durable plastics. Galvanized steel offers excellent corrosion resistance, making it suitable for use in humid or damp environments commonly found in HVAC systems.

Stainless steel, on the other hand, provides superior strength and durability, allowing the clips to endure high levels of stress and mechanical force. For applications where lightweight and chemical resistance are required, our plastic retainer clips, often made from materials like nylon or polypropylene, are an ideal choice. These materials also offer good insulation properties, preventing the transfer of heat or cold through the clips. The combination of these high-quality materials ensures that our HVAC retainer clips perform reliably over the long term.

Meticulous Manufacturing Process of Retainer Clips

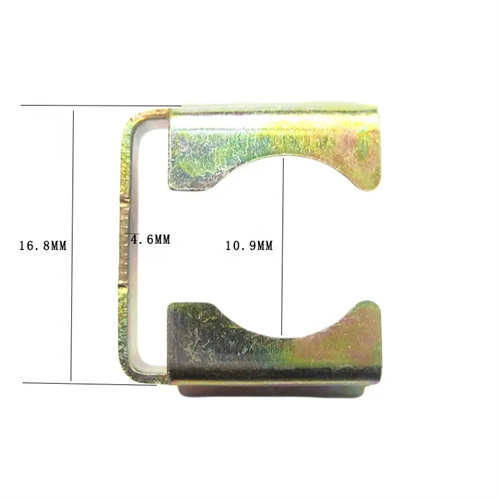

The production of our HVAC Retainer Clips involves a meticulous manufacturing process that combines advanced technology with strict quality control. We begin by sourcing premium raw materials that meet our high standards for performance and durability. For metal clips, the manufacturing process includes precision stamping and forming, using state-of-the-art equipment to create the desired shape with high accuracy.

Plastic clips are produced through injection molding, where the material is melted and injected into molds under high pressure to achieve consistent dimensions and a smooth finish. After fabrication, each clip undergoes a series of quality checks, including inspections for dimensional accuracy, surface defects, and proper functionality. Any clip that fails to meet our strict criteria is rejected, ensuring that only the highest-quality products reach our customers.

Rigorous Quality Control of Retainer Clips

Quality control is at the heart of our production of HVAC Retainer Clips. We have implemented a comprehensive quality control system that covers every aspect of the manufacturing process, from raw material inspection to the final product. Our quality control team uses a variety of advanced testing equipment and techniques to ensure the integrity of each clip.

Raw materials are tested for their chemical composition, mechanical properties, and corrosion resistance. During the manufacturing process, in-line inspections are carried out regularly to monitor the production quality, including the precision of the stamping or molding process and the assembly of components. After production, each clip undergoes a series of performance tests, such as load-bearing tests to verify its holding capacity, fatigue tests to assess its durability under repeated use, and salt spray tests to evaluate its corrosion resistance. Only clips that pass all these rigorous tests are approved for shipment, ensuring that our customers receive reliable and long-lasting products.

Comprehensive Customer Support for Retainer Clips

We are committed to providing comprehensive customer support for our HVAC Retainer Clips. Our team of experts is available to assist customers throughout the entire process, from the initial product selection to after-sales service. We offer detailed technical advice on choosing the right type of retainer clip for specific HVAC applications, taking into account factors such as duct size, panel thickness, and environmental conditions.

In case of any issues or concerns, our responsive after-sales service team is ready to provide prompt solutions. Whether it’s a question about product performance, a need for replacement parts, or assistance with installation, we strive to ensure that our customers are completely satisfied with our products and services. We also offer training programs for installers and maintenance personnel, enabling them to use our retainer clips effectively and optimize the performance of HVAC systems. Our goal is to build long-term partnerships with our customers based on trust, reliability, and exceptional support in the HVAC industry.