Unmatched Design Flexibility of Custom Spring Clips

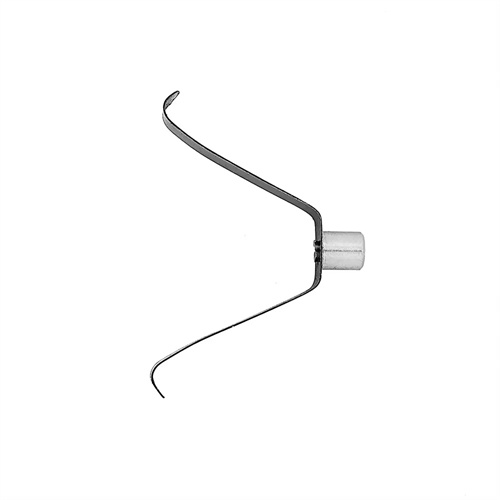

Our Custom Spring Clips offer unmatched design flexibility, tailored to meet the most unique and specific application requirements. Unlike off – the – shelf options, our custom approach allows us to work closely with clients to understand their exact needs. Whether it’s a specialized shape required to fit an irregularly sized component, a specific clamping force needed for a high – stress environment, or a unique functionality for a niche industry, our team of engineers can bring any concept to life.

We use advanced 3D modeling and design software to create detailed prototypes, enabling clients to visualize the final product before production begins. This collaborative design process ensures that every aspect of the spring clip, from its dimensions to its mechanical properties, is optimized for the intended application. The result is a custom – made snap buttons spring clip that not only fits perfectly but also performs exceptionally, providing a solution that standard clips simply cannot offer.

The Art of Precision Stamping in Spring Clip Production

Precision stamping is the cornerstone of our Custom Spring Clips production, and it’s an art form that we have mastered over the years. Our state – of – the – art stamping facilities are equipped with high – precision presses and cutting – edge tooling, allowing us to produce spring clips with minute tolerances. The process begins with the selection of high – quality raw materials, which are then fed into the stamping machines.

Using custom – designed dies, the metal is shaped into the desired form of the spring clip with extreme accuracy. The stamping process ensures consistent quality, as each clip is produced to the exact same specifications. Our skilled technicians closely monitor the stamping process, making real – time adjustments to ensure that every snap buttons spring clip meets our stringent quality standards. This precision stamping technique not only guarantees the accuracy of the clip’s dimensions but also enhances its mechanical performance, making it suitable for even the most demanding applications.

Optimal Material Selection for Custom Spring Clips

Selecting the right material is crucial for the performance of our Custom Spring Clips, and we offer a wide range of options to suit different applications. For applications that require high strength and durability, materials such as stainless steel, spring steel, and alloy steel are excellent choices. These metals can withstand heavy loads, vibrations, and harsh environmental conditions, making them ideal for industrial and automotive use.

In applications where weight is a concern or where corrosion resistance is paramount, we recommend materials like aluminum alloys or high – performance plastics. For example, aluminum alloy spring clips are lightweight yet strong, making them suitable for aerospace and consumer electronics applications. Specialized plastics, such as nylon and polycarbonate, offer good chemical resistance and electrical insulation properties, making them perfect for electrical and medical device applications. Our experts work with clients to select the most appropriate material, ensuring that the custom snap buttons spring clip performs optimally in its intended environment.

Diverse Applications of Custom Spring Clips

Our Custom Spring Clips find diverse applications across a multitude of industries, thanks to their ability to be tailored to unique needs. In the automotive industry, custom spring clips are used to secure hoses, cables, and various components, ensuring a perfect fit and reliable performance under the demanding conditions of vehicle operation.

In the electronics sector, they are essential for fastening delicate components on printed circuit boards, providing a secure hold without causing damage. The aerospace industry relies on our custom spring clips for lightweight yet strong fastening solutions in aircraft assemblies. Even in the medical field, custom spring clips are used in devices where precision and biocompatibility are crucial. From large – scale industrial applications to highly specialized niche uses, our custom snap buttons spring clips offer a reliable and effective fastening solution.

Rigorous Quality Control of Custom Spring Clips

Quality control is at the heart of our production of Custom Spring Clips. We have implemented a comprehensive quality control system that monitors every stage of the manufacturing process, from raw material inspection to the final product. Our quality control team uses advanced testing equipment, such as coordinate measuring machines (CMMs), tensile testers, and fatigue testers, to ensure the integrity of each clip.

Raw materials are tested for their chemical composition, mechanical properties, and compatibility with the intended application. During the stamping process, in – line inspections are carried out regularly to monitor the dimensional accuracy, surface finish, and forming quality of the clips. After production, each snap buttons spring clip undergoes a series of performance tests, including load – bearing tests, corrosion resistance tests, and functional tests. Only clips that pass all these rigorous tests are approved for shipment, ensuring that our customers receive products of the highest quality.

Comprehensive Customer Support for Custom Spring Clips

We are committed to providing comprehensive customer support for our Custom Spring Clips. Our team of experts is available to assist customers throughout the entire process, from the initial design consultation to after – sales service. We offer detailed technical advice on choosing the right design, material, and manufacturing process for specific applications.

In case of any issues or concerns, our responsive after – sales service team is ready to provide prompt solutions. Whether it’s a question about product performance, a need for replacement parts, or assistance with installation, we strive to ensure that our customers are completely satisfied with our products and services. We also offer ongoing support and maintenance services, as well as the option for further customization based on evolving needs. Our goal is to build long – term partnerships with our customers, based on trust, reliability, and exceptional support for their unique applications.