Identify Your Application Requirements for Spring Steel Clips

Before selecting spring steel clips, the first and most crucial step is to identify the specific requirements of your application. We need to consider what the clips will be used for. Are they meant to secure hoses in an automotive engine, fasten components in industrial machinery, or hold parts together in a consumer product? Different applications demand varying levels of clamping force, durability, and functionality from the spring steel clips.

For example, if the clips will be used in a high – vibration environment like a running engine, they need to have excellent fatigue resistance to prevent failure over time. In contrast, for a less demanding application such as holding lightweight parts in a simple assembly, a clip with lower strength requirements might suffice. By clearly defining the purpose and expected performance of the clips, we can narrow down our options and focus on finding the most suitable ones.

Consider the Material Properties of Spring Steel Clips

The material properties of spring steel clips play a significant role in their performance. Spring steel comes in different grades, each with unique characteristics. We should pay attention to factors such as tensile strength, elasticity, and corrosion resistance. High – tensile – strength spring steel is ideal for applications that require the clip to withstand heavy loads without deforming.

Elasticity is crucial as it determines how well the clip can return to its original shape after being deformed, ensuring a consistent clamping force. When the clips will be exposed to moisture, chemicals, or outdoor elements, corrosion – resistant spring steel, perhaps with added alloying elements or surface treatments, becomes a necessity. Understanding these material properties helps us match the spring steel clips to the environmental and mechanical demands of our application.

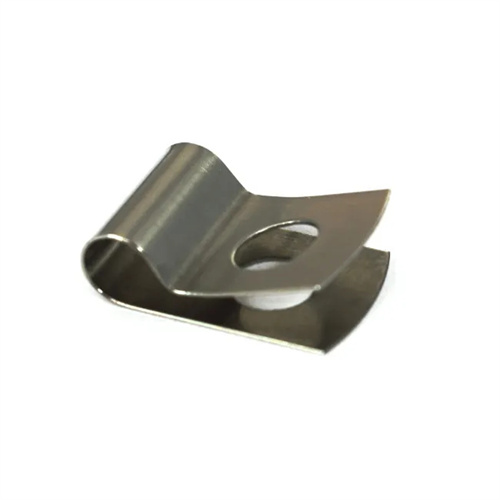

Evaluate the Size and Dimensions of Spring Steel Clips

Size and dimensions are often overlooked but essential factors when choosing spring steel clips. We must measure the objects that the clips will secure accurately. The clip’s opening size should be slightly larger than the diameter or thickness of the item to be fastened to allow for easy installation, yet not so large that it fails to provide a secure hold.

In addition, the overall length, width, and thickness of the clip matter, especially in applications where space is limited. For instance, in tight – fitting electronic assemblies, a compact and low – profile spring steel clip is required. By carefully evaluating the size and dimensions based on our application’s spatial constraints and the size of the components to be secured, we can avoid choosing clips that are either too big or too small, ensuring a proper fit and optimal performance.

Assess the Operating Environment of Spring Steel Clips

The operating environment in which the spring steel clips will function has a profound impact on their lifespan and effectiveness. We need to consider factors like temperature, humidity, exposure to chemicals, and mechanical stress. In high – temperature environments, such as near industrial furnaces or in automotive exhaust systems, the spring steel clips should be able to maintain their mechanical properties without losing strength or elasticity.

In humid or corrosive environments, corrosion – resistant clips are a must to prevent rust and degradation. If the clips will be subjected to frequent vibrations or impacts, they should have high fatigue resistance. By thoroughly assessing the operating environment, we can select spring steel clips that are engineered to thrive in those specific conditions, reducing the risk of premature failure and ensuring long – term reliability.

Understand the Manufacturing Process of Spring Steel Clips

The manufacturing process of spring steel clips influences their quality and consistency. We should look for clips that are produced using advanced manufacturing techniques and strict quality control measures. Precision stamping and forming processes can create clips with accurate dimensions and consistent shapes, which are essential for reliable performance.

Heat treatment is another critical process as it can optimize the mechanical properties of the spring steel, enhancing its strength, hardness, and elasticity. Additionally, surface treatments like plating or coating can improve corrosion resistance and appearance. By understanding the manufacturing process and choosing clips from reputable manufacturers who adhere to high – quality standards, we can have confidence in the durability and performance of the spring steel clips we select.

Consider the Brand Reputation and Customer Support for Spring Steel Clips

Finally, we should not underestimate the importance of brand reputation and customer support when choosing spring steel clips. A well – established brand with a good reputation is more likely to offer high – quality products that meet or exceed industry standards. Reading customer reviews and testimonials can provide valuable insights into the real – world performance and reliability of the clips.

Moreover, excellent customer support is crucial. If we encounter any issues during the selection, installation, or use of the spring steel clips, a responsive and knowledgeable customer support team can provide timely assistance, troubleshooting advice, and solutions. Brands that offer comprehensive warranties and after – sales services demonstrate their commitment to customer satisfaction, giving us peace of mind in our purchase decision.